Revolutionizing Logistics: How Warehouse Automation Robots are Shaping the Future of Supply Chains

The logistics industry is undergoing a transformative shift with the advent of warehouse automation robots, fundamentally reshaping supply chain operations. According to a recent report by McKinsey, the adoption of automation in warehouses can increase productivity by up to 30%, driving efficiency and reducing labor costs. Furthermore, a study by Research and Markets indicates that the global market for warehouse automation is projected to reach $30 billion by 2026, highlighting the growing reliance on technology in this sector.

The logistics industry is undergoing a transformative shift with the advent of warehouse automation robots, fundamentally reshaping supply chain operations. According to a recent report by McKinsey, the adoption of automation in warehouses can increase productivity by up to 30%, driving efficiency and reducing labor costs. Furthermore, a study by Research and Markets indicates that the global market for warehouse automation is projected to reach $30 billion by 2026, highlighting the growing reliance on technology in this sector.

As businesses strive to meet the demands of faster delivery times and improved accuracy, warehouse automation robots are becoming essential tools in optimizing inventory management and streamlining operations. These innovations not only enhance operational agility but also support the broader trend of digital transformation within supply chains, positioning companies to better navigate the complexities of the modern marketplace.

Understanding the Basics: What are Warehouse Automation Robots?

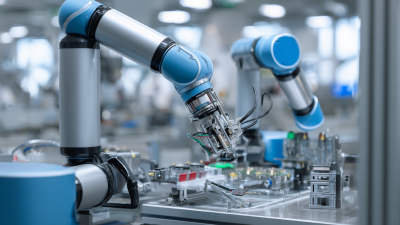

Warehouse automation robots have become a critical component in advancing supply chain efficiency and productivity. These robots utilize sophisticated technologies, including artificial intelligence and machine learning, to perform various tasks such as sorting, packing, and inventory management. According to recent industry reports, automation in logistics is expected to enhance operational efficiency by up to 30%, which significantly lowers costs and improves delivery times for businesses.

Warehouse automation robots have become a critical component in advancing supply chain efficiency and productivity. These robots utilize sophisticated technologies, including artificial intelligence and machine learning, to perform various tasks such as sorting, packing, and inventory management. According to recent industry reports, automation in logistics is expected to enhance operational efficiency by up to 30%, which significantly lowers costs and improves delivery times for businesses.

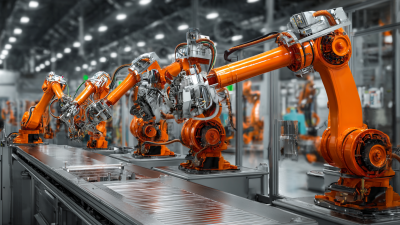

The rise of automation is evident globally, with countries investing heavily in robotic systems to streamline manufacturing processes and logistics operations. For instance, China's recent surge in automation driven by substantial policy support and investment has enabled factories to reduce production costs while maintaining high product quality. This trend is reflected in the increasing adoption of intelligent robot systems that can understand and adapt to their environment, paving the way for innovation in both industrial and residential applications. As the logistics sector embraces these technologies, companies are better equipped to meet evolving consumer demands while maximizing their competitive edge in the marketplace.

Key Benefits of Implementing Warehouse Automation in Logistics

The logistics landscape is undergoing a transformative shift, driven by the adoption of warehouse automation technologies. As the global e-commerce logistics market is projected to soar from $441.55 billion in 2024 to an astounding $1,903.08 billion by 2032, with a compound annual growth rate of 20.04%, businesses are increasingly recognizing the critical role of automated solutions. Integrating high-tech automated warehousing systems not only helps in streamlining operations but also addresses the pressing need for cost efficiency and rapid adaptability in a fast-paced market.

One of the primary benefits of implementing warehouse automation is the significant reduction in operational costs. Automated systems ensure higher accuracy in inventory management, minimizing errors and losses associated with manual processes. Additionally, they enable faster order processing and fulfillment, which is vital in meeting consumer expectations for speed and reliability. As logistics providers harness the intelligence of automated storage systems, they can better respond to fluctuating market demands while optimizing their overall supply chain efficiency, paving the way for sustainable growth in the industry.

Integrating Robotics with Existing Supply Chain Systems

The integration of robotics into existing supply chain systems is a game-changer for logistics operations. According to a report by McKinsey & Company, companies that adopt advanced automation technologies in their warehouses can improve productivity by up to 30%. By seamlessly integrating robotic solutions, businesses can streamline operations, reduce manual errors, and achieve faster order fulfillment timelines.

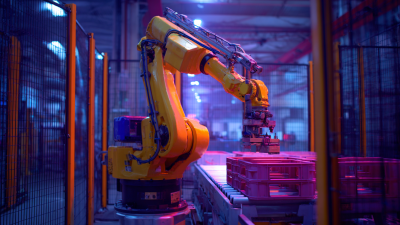

Moreover, the adoption of warehouse automation is projected to grow, with the global warehouse automation market expected to reach $30 billion by 2026, according to a research report by LogisticsIQ. This shift reflects a significant recognition within the industry of robotics’ potential to complement traditional supply chain processes. By incorporating automated systems, such as autonomous mobile robots (AMRs) and robotic arms, companies can efficiently manage inventory, optimize space utilization, and significantly lower operational costs while meeting the growing demands of e-commerce and fast delivery services.

This strategic blending of robotics and supply chain operations not only enhances efficiency but also equips businesses to adapt to the complexities of modern logistics. As companies invest in this transformative technology, the focus will be on creating agile systems that can respond dynamically to market changes and consumer needs.

Evaluating the Cost vs. Efficiency of Warehouse Robots

The integration of warehouse automation robots into supply chains has sparked a debate about their cost versus efficiency. Initially, the high upfront investment for robotic systems can raise concerns among businesses, especially smaller operations. However, these costs should be weighed against the long-term benefits. Automated robots significantly reduce labor costs by minimizing human error and increasing throughput, which can offset the initial expenditure over time. The capabilities of these robots resonate well with the increasing demand for rapid order fulfillment, ensuring that companies can meet consumer expectations effectively.

Moreover, the efficiency derived from warehouse robots extends beyond mere speed. Advanced automation systems streamline inventory management, enhance accuracy in picking and packing, and optimize space utilization within warehouses. With data-driven algorithms, robots can adapt to real-time changes in demand and logistics, leading to a more agile supply chain. As businesses evaluate the financial implications of adopting robotic technology, it becomes evident that the improved efficiency gained through automation not only enhances productivity but also fosters a competitive edge in the market. Hence, the decision to implement warehouse robots is increasingly seen as a strategic investment rather than a mere expense.

Future Trends: The Next Generation of Logistics Automation Technology

The landscape of logistics is evolving rapidly, driven by the adoption of advanced automation technologies. The next generation of logistics automation focuses on enhancing efficiency, accuracy, and speed through innovative solutions such as autonomous mobile robots (AMRs), artificial intelligence (AI), and the Internet of Things (IoT). These technologies are not only transforming warehouse operations but are also creating more responsive and dynamic supply chains. As businesses increasingly invest in these capabilities, the potential for improving inventory management and delivery accuracy continues to grow.

**Tips:** When considering automation, assess your specific operational needs to ensure you select technologies that align with your warehouse processes. Additionally, investing in employee training is crucial; human oversight remains important to address tasks that robots may struggle with.

Looking ahead, we can expect further advancements such as collaborative robots (cobots) that work alongside human workers, enhancing productivity while reducing the risk of workplace injuries. Integration of big data analytics will also play a pivotal role in predicting demand and optimizing logistics operations, making supply chains more resilient to disruptions. Embracing these trends will be essential for companies aiming to stay competitive in a rapidly changing market.

**Tips:** Stay informed about emerging technologies through industry forums and publications to identify potential upgrades. Collaborating with technology providers can help streamline the integration process, ensuring a smoother transition to automated systems.

Revolutionizing Logistics: How Warehouse Automation Robots are Shaping the Future of Supply Chains

| Technology Type | Application | Benefits | Market Growth (%) | Adoption Rate (%) |

|---|---|---|---|---|

| Automated Guided Vehicles (AGVs) | Material Transport | Increased Efficiency | 20% | 30% |

| Robotic Picking Systems | Order Fulfillment | Accuracy and Speed | 25% | 40% |

| Automated Storage and Retrieval Systems (ASRS) | Inventory Management | Space Optimization | 18% | 28% |

| Drones | Stocktaking and Delivery | Reduced Labor Costs | 30% | 15% |

| Artificial Intelligence (AI) | Predictive Analytics | Enhanced Decision-Making | 22% | 35% |

Related Posts

-

Future of Warehouse Robots at China's 138th Canton Fair 2025 Industry Insights and Market Growth Trends

-

Top 5 Robotics Companies Driving $110 Billion Global Market Growth in 2023

-

How to Enhance Manufacturing Efficiency with Cobot Robots in Your Business

-

Exploring the Future of Palletizing Robots at the 138th China Import and Export Fair 2025

-

The Future of Work How Industrial Robots are Transforming Manufacturing Industries

-

Exploring the Future of Online Robots in Everyday Life and Digital Interactions

Smart Robotics brand movie

Watch video