Top 10 Picking Robots Revolutionizing Warehouse Efficiency in 2023

In recent years, the logistics and warehouse industry has undergone a remarkable transformation, largely due to the rise of picking robots. According to a report by ResearchAndMarkets, the global market for warehouse automation, which prominently includes picking robots, is projected to reach $30 billion by 2026, growing at a compound annual growth rate (CAGR) of over 14%. This surge is driven by the increasing need for efficiency and accuracy in order fulfillment, especially in the wake of the e-commerce boom and changing consumer demands for faster deliveries.

Experts in the field are taking notice of this trend. Dr. Emily Chen, a leading researcher in robotics and automation at the Robotics Institute, stated, "The adoption of picking robots is not just a trend; it's a paradigm shift that enhances operational efficiency and reduces labor costs significantly." This statement underscores the impact that picking robots are having in warehouses across the globe. As organizations strive to handle higher volumes of inventory and streamline their processes, the integration of these advanced technologies is no longer optional but essential.

As we delve into the top 10 picking robots revolutionizing warehouse efficiency in 2023, it becomes evident that these innovations are not only transforming how goods are picked and processed but also setting new standards for operational excellence in the logistics sector. The capabilities of these robots reflect a future where automation and human labor work in tandem, leading to a redefined landscape of warehouse management.

Introduction to Picking Robots in Warehousing

In recent years, the warehousing industry has witnessed a significant transformation driven by the integration of advanced technologies, particularly picking robots. These automated systems are designed to optimize efficiency in order fulfillment processes, reducing human labor and minimizing errors associated with manual picking. As warehouses face increasing demands for faster delivery times, the introduction of picking robots has become a crucial solution to streamline operations.

Picking robots utilize sophisticated algorithms and machine learning capabilities to navigate warehouse environments and identify products accurately. Through the use of sensors and cameras, these robots can locate items, assess their sizes, and pick them without damaging the goods. This automation not only enhances speed and accuracy but also allows warehouse staff to focus on more complex tasks that require human judgment and oversight. As a result, the overall productivity of warehouse operations significantly improves, leading to reduced operational costs and better service for customers.

Moreover, the implementation of picking robots contributes to a safer working environment. By handling tedious and physically demanding tasks, these robots help to reduce the risk of injuries that can occur in busy warehouse settings. This shift not only benefits the workforce but also allows organizations to allocate resources more effectively, ensuring that human workers can engage in activities that leverage their skills, creativity, and expertise. The evolution of picking robots marks a new era in warehousing, promising enhanced efficiency and improved workforce dynamics.

Top 10 Picking Robots Revolutionizing Warehouse Efficiency in 2023

This chart illustrates the efficiency improvement percentages achieved by the top 10 picking robots in warehouse operations in 2023. The data represents a comparative analysis of how these robots have enhanced productivity in various metrics such as speed, accuracy, and order fulfillment.

Key Features of Cutting-Edge Picking Robots

The evolution of picking robots has significantly transformed the landscape of warehouse operations, enhancing efficiency and accuracy. One of the key features of cutting-edge picking robots is their sophisticated sensor technology. These robots are equipped with advanced LiDAR and vision systems that allow them to accurately identify and locate items within a cluttered environment. This capability not only reduces the time taken to find products but also minimizes the risk of errors associated with manual picking.

Another important aspect of modern picking robots is their adaptability and flexibility in workflow integration. Unlike traditional automation, these robots can seamlessly adapt to different product types and sizes, making them suitable for diverse inventory systems. They can be easily reprogrammed or upgraded to accommodate changes in warehouse layouts or product lines. This adaptability allows warehouses to optimize space and improve operational efficiency, ultimately leading to faster turnaround times and enhanced productivity in fulfillment processes.

Top 10 Picking Robots Transforming Warehouse Operations

In 2023, the landscape of warehouse operations is being transformed by cutting-edge picking robots that are enhancing efficiency and accuracy. These intelligent machines utilize advanced algorithms and AI to navigate complex storage environments, significantly reducing the time employees spend locating and retrieving items. By automating the picking process, warehouses can maximize throughput while minimizing labor costs, allowing human workers to focus on more complex tasks that require problem-solving and decision-making skills.

As the demand for faster and more efficient supply chains grows, the evolution of picking robots has led to innovations such as collaborative robots, or cobots, that work alongside human staff. These robots are designed to assist rather than replace workers, enhancing productivity levels without compromising workspace safety. With real-time data analytics, they learn and adapt to changing inventory patterns, improving their picking accuracy over time. The integration of these robots not only streamlines operations but also enhances the overall reliability and speed of order fulfillment, an essential factor in today’s competitive marketplace.

Top 10 Picking Robots Revolutionizing Warehouse Efficiency in 2023

| Robot Model | Max Payload (kg) | Speed (items/min) | Battery Life (hours) | Navigation Type |

|---|---|---|---|---|

| Model A | 15 | 30 | 8 | Lidar |

| Model B | 20 | 40 | 6 | Vision-based |

| Model C | 25 | 35 | 12 | GPS |

| Model D | 18 | 45 | 10 | Magnetic |

| Model E | 22 | 50 | 9 | Laser |

| Model F | 19 | 32 | 11 | Vision-based |

| Model G | 24 | 40 | 7 | Lidar |

| Model H | 27 | 28 | 13 | GPS |

| Model I | 20 | 33 | 8 | Magnetic |

| Model J | 30 | 36 | 10 | Laser |

Impact of Picking Robots on Warehouse Efficiency

The rise of picking robots in warehouses marks a significant leap in operational efficiency. These advanced robots are designed to automate the picking process, which is often labor-intensive and time-consuming. By integrating robotic systems, warehouses can achieve faster order fulfillment, minimizing the time between receiving an order and shipping it out. This acceleration not only boosts productivity but also enhances customer satisfaction, as timely deliveries become more feasible.

Moreover, picking robots improve accuracy in inventory management. Equipped with sophisticated sensors and artificial intelligence, these robots can precisely identify, pick, and sort items, reducing the likelihood of human error. This heightened accuracy contributes to better stock control and fewer returns, ultimately resulting in cost savings for warehouse operators. As companies increasingly adopt these technological solutions, they are not just reshaping the way warehouses operate; they are setting new standards in efficiency and reliability that redefine the logistics sector.

Future Trends in Warehouse Automation and Robotics

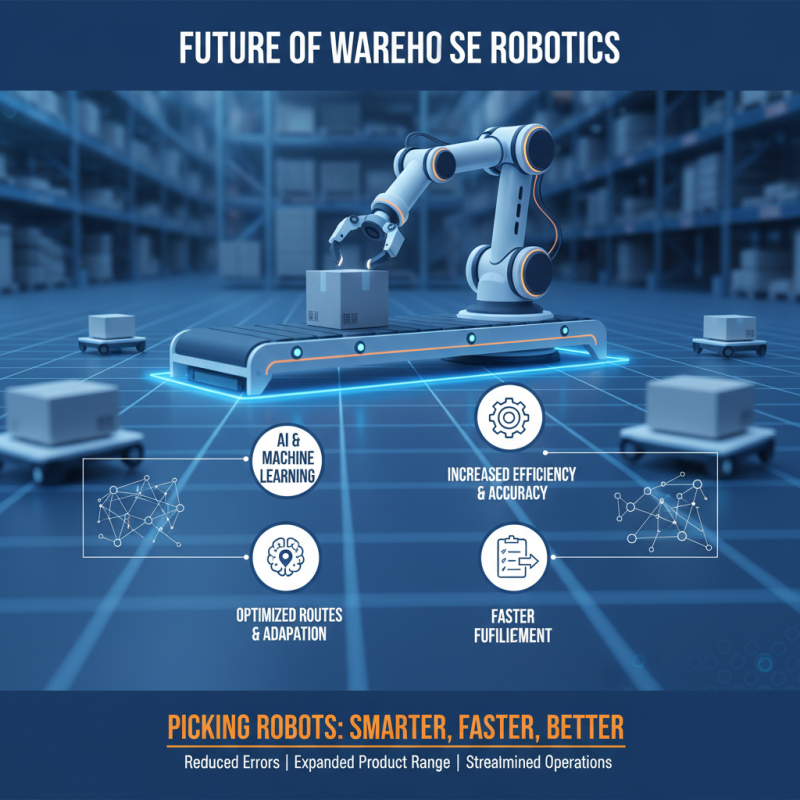

As warehouses continue to embrace automation, the future of robotics in warehouse management is poised for significant innovation. The rise of picking robots is central to this evolution, facilitating increased efficiency and accuracy in order fulfillment. By integrating advanced technologies such as artificial intelligence and machine learning, these robots can adapt to various tasks, optimize their routes, and handle an ever-expanding range of products. This not only streamlines operations but also reduces human error, ultimately leading to faster processing times and enhanced productivity.

Moreover, the trend toward collaborative robotics is gaining momentum in warehouse settings. Rather than replacing human workers, these robots are designed to work alongside them, assisting with heavy lifting and repetitive tasks. This partnership not only alleviates physical strain on employees but also allows them to focus on more complex responsibilities that require human insights. As this symbiotic relationship develops, warehouses are expected to become more agile, capable of responding swiftly to changing consumer demands and market conditions. The integration of Internet of Things (IoT) capabilities into these systems further enhances their potential, leading to smarter inventory management and operational oversight.

Related Posts

-

Future of Warehouse Robots at China's 138th Canton Fair 2025 Industry Insights and Market Growth Trends

-

Top 5 Robotics Companies Driving $110 Billion Global Market Growth in 2023

-

Revolutionizing Logistics: How Warehouse Automation Robots are Shaping the Future of Supply Chains

-

10 Tips for Choosing the Right Industrial Robotic Arm for Your Business

-

Why Industrial Robotic Arms Are Revolutionizing Modern Manufacturing Processes

-

Revolutionizing Supply Chains: How Warehouse Robots Are Shaping the Future of Logistics

Smart Robotics brand movie

Watch video