Top Picking Robots for Efficient Automation in Warehousing and Logistics?

In today's fast-paced world, efficiency is key in warehousing and logistics. The rise of picking robots has revolutionized these sectors. These robotic systems streamline operations, reduce human error, and enhance productivity. Many companies are turning to picking robots to handle high volumes of goods. The need for automation is more pressing than ever.

Picking robots can navigate through aisles, identify items, and pick them with precision. They operate tirelessly, working around the clock. However, the integration of these robots is not without challenges. Maintaining them requires careful planning. Workers may feel uneasy about these machines taking over tasks. The balance between automation and the human touch is crucial.

As we explore the top picking robots available today, it's essential to consider both their advantages and limitations. These robots can improve efficiency, but they also require a significant investment. Companies must weigh the benefits against potential drawbacks. The future of warehousing will heavily depend on how well these robots fit into existing systems.

Top Picking Robots Overview: Definition and Importance in Warehousing

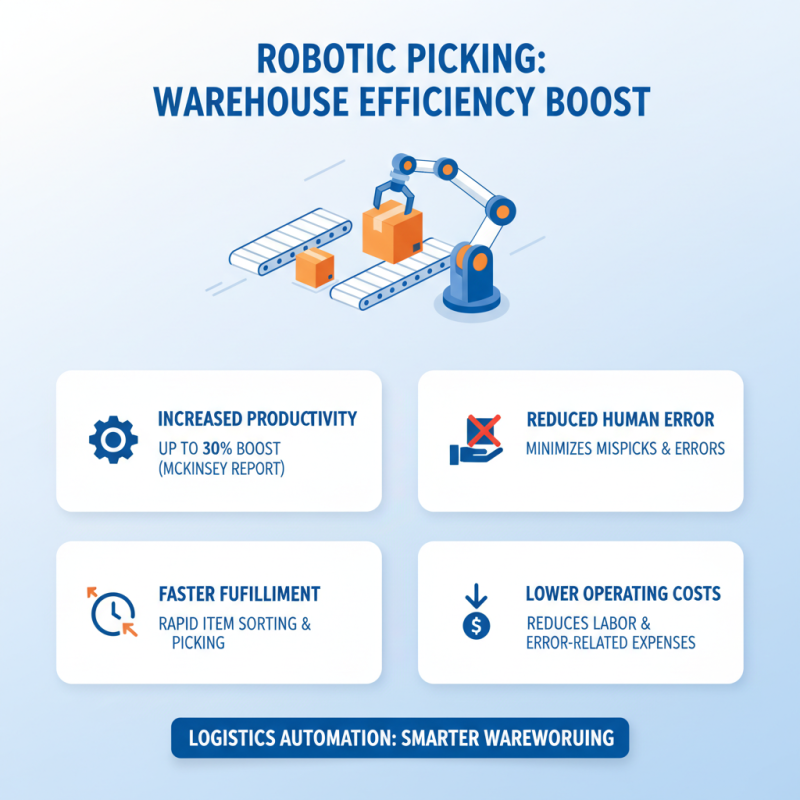

In recent years, the role of picking robots in warehousing has gained significant attention. These robots improve efficiency and reduce labor costs. According to a report by McKinsey, automation could increase productivity in warehousing by up to 30%. As e-commerce grows, companies need reliable solutions for inventory management. Picking robots offer both speed and precision in handling goods.

The importance of picking robots extends beyond just speed. They also enhance safety in warehouses. Workers face risks while manually lifting heavy items. Robots alleviate these dangers, allowing humans to focus on complex tasks. A study published by GlobalData shows that 70% of warehouses that implemented automation reported a decrease in worker injuries.

However, the transition to automation is not without challenges. Many organizations face integration issues with existing systems. Training workers to operate new technology requires time and resources. There are also concerns about the upfront costs. A report from Logistics Management emphasizes that these challenges must be analyzed carefully. Companies should weigh the long-term gains against initial investment hurdles. Addressing these factors is crucial for successful implementation.

Top Picking Robots Overview: Definition and Importance in Warehousing

| Robot Model | Picking Speed (Items/Hour) | Weight Capacity (kg) | Battery Life (Hours) | Navigation Technology | Common Use Cases |

|---|---|---|---|---|---|

| Model A | 1200 | 100 | 8 | Lidar | Order Fulfillment, Inventory Management |

| Model B | 950 | 150 | 10 | Marker-Based | Retail, E-Commerce |

| Model C | 1500 | 80 | 6 | SLAM | Pharmaceuticals, Food & Beverage |

| Model D | 1100 | 120 | 12 | Infrared | Manufacturing, Large Warehouses |

| Model E | 1350 | 60 | 5 | Vision-Based | Last-Mile Delivery, Automation |

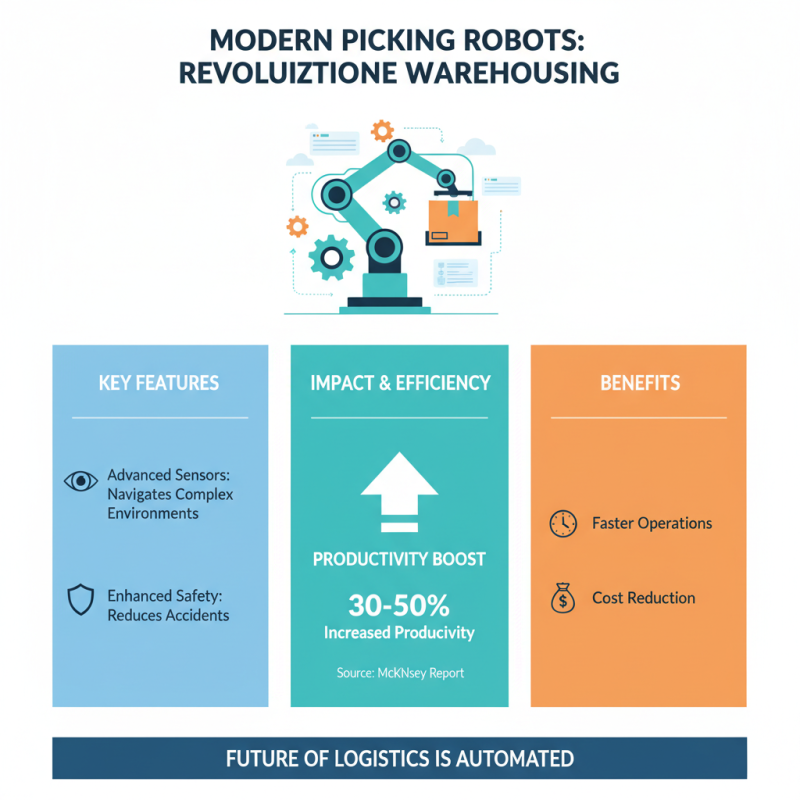

Key Features of Modern Picking Robots: Technology and Design Elements

Modern picking robots are revolutionizing the warehousing and logistics sectors. Key features define their efficiency and effectiveness. Advanced sensors play a vital role, allowing robots to navigate complex environments with ease. These sensors enhance safety and reduce accidents, which is crucial in busy warehouses. A report by McKinsey shows that automation can boost productivity by 30% to 50%.

Another important aspect is the design of these robots. Ergonomics and modularity are essential for optimizing workflows. Picking robots must be adaptable to various goods and environments. They often come equipped with AI algorithms to improve decision-making. However, some robots still face challenges with irregularly shaped items. This is an area that requires ongoing development.

**Tips:** When considering picking robots, focus on their integration with existing systems. Compatibility is key to maximizing efficiency. Regular updates to software can also enhance their performance and capabilities. Continuous training for human operators is necessary to work seamlessly alongside robots.

Types of Picking Robots: Autonomous Mobile Robots vs. Robotic Arms

Picking robots have transformed warehousing. Two main types are autonomous mobile robots (AMRs) and robotic arms.

AMRs move freely across the warehouse. They can navigate complex layouts, avoiding obstacles. These robots transport goods from one location to another, improving efficiency.

Their adaptability allows them to handle various tasks, which is crucial in dynamic environments.

In contrast,

robotic arms excel at specific tasks. They are designed for precision. These robots can pick and place items with great accuracy. However, they are typically stationary and need a set workspace.

This limitation can hinder flexibility. Moreover, robotic arms often require extensive programming and maintenance. Operators must ensure they are functioning correctly to avoid delays.

Each type has strengths and weaknesses.

AMRs are versatile but may struggle with delicate items.

Robotic arms are precise but restricted by their environment. Businesses must weigh these factors carefully.

Selecting the right robot depends on unique warehouse needs. It invites reflection on the balance between efficiency and capability.

Benefits of Implementing Picking Robots in Logistics and Warehousing

Implementing picking robots in logistics and warehousing offers several benefits that enhance efficiency and accuracy. According to a report from McKinsey, automation can increase warehouse productivity by up to 30%. These robots handle repetitive tasks like picking and sorting items. This reduces human error, which is often a significant issue. For instance, mispicks can account for the largest portion of operating costs in warehouse management.

Moreover, studies show that automated systems can operate 24/7 without fatigue. This capability leads to a higher throughput. A report by AMR Research notes that companies utilizing automated picking solutions report a 20% increase in order fulfillment speed. However, these systems require significant upfront investment, which can be daunting for smaller operations. Balancing cost and efficiency is essential.

It's also crucial to consider the integration process. Many warehouses struggle to incorporate new technology smoothly. This can lead to disruptions in daily operations. Training staff is another challenge. Without proper training, the benefits of automation may not be fully realized. Thus, while the advantages of picking robots are promising, companies must approach implementation thoughtfully.

Future Trends in Picking Robot Technology and Automation Solutions

The future of picking robot technology is bright. As warehouses evolve, automatization becomes essential. These robots enhance efficiency and reduce human errors. Current trends show increased flexibility in design. Robots can now adapt to various product types and sizes. This adaptability allows for more streamlined operations.

However, challenges remain. Not all robots can handle complex tasks. Integration with existing systems can be difficult. Also, the cost of advanced robots may deter many businesses. Companies must weigh the benefits against investment risks. Adoption is uneven across industries. Some sectors move faster than others.

Moreover, as technology evolves, human roles may shift. Workers will need new skills for collaboration with robots. This transition could lead to resistance or confusion. Understanding these dynamics is essential for a smooth integration. The future of warehousing will likely be a blend of human creativity and robotic efficiency.

Top Picking Robots Adoption Rates in Warehousing and Logistics (2023)

Related Posts

-

2025 Top 5 Picking Robots for Efficient Agricultural Automation

-

Top 10 Picking Robots Revolutionizing Warehouse Efficiency in 2023

-

What is a Packaging Robot and How It Revolutionizes the Packaging Industry

-

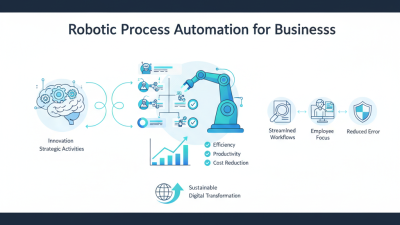

The Ultimate Guide to Robotic Process Automation Software for Businesses

-

Top Robotic Process Automation Software to Streamline Your Business Operations

-

Top 10 Benefits of Robotic Automation for Modern Businesses

Smart Robotics brand movie

Watch video