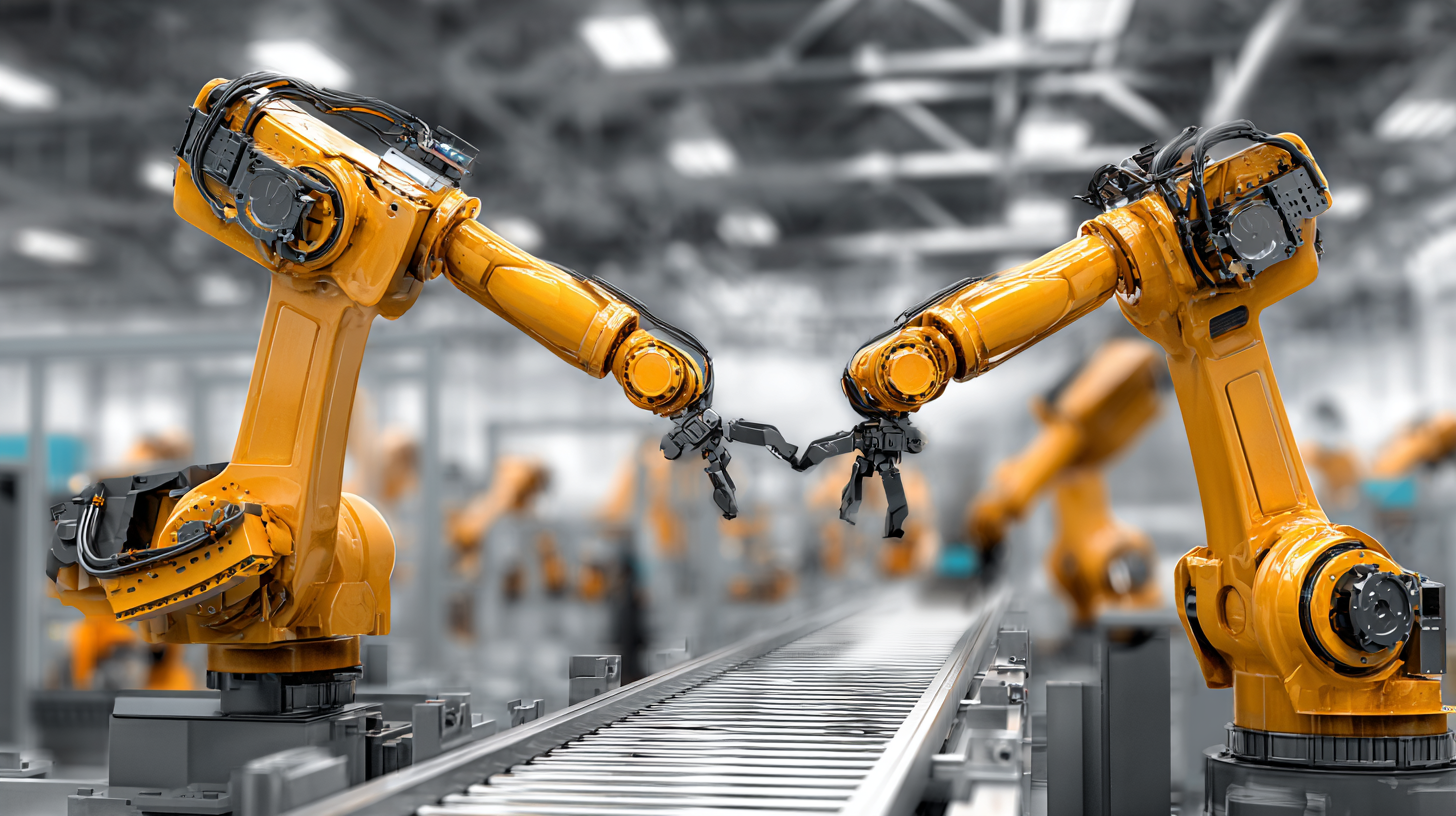

The Future of Work How Industrial Robots are Transforming Manufacturing Industries

The advent of industrial robots has fundamentally reshaped the landscape of manufacturing industries, heralding a new era of efficiency and innovation. According to a report by the International Federation of Robotics (IFR), the global stock of industrial robots surpassed 3 million units in operation by 2020, demonstrating a significant 12% annual growth rate. This rapid adoption is driven by the increasing need for automation to enhance productivity and reduce operational costs. A McKinsey report highlights that companies implementing robotics can experience productivity gains of up to 30%. As businesses strive to remain competitive in an ever-evolving market, understanding how to effectively integrate industrial robots into existing workflows has become essential. Transitioning to a robotic workforce not only optimizes manufacturing processes but also addresses labor shortages and safety concerns by relegating repetitive, hazardous tasks to machines, thereby paving the way for a more skilled and adaptive workforce.

The Role of Industrial Robots in Enhancing Manufacturing Efficiency and Productivity

Industrial robots are playing a pivotal role in enhancing manufacturing efficiency and productivity across various sectors. According to recent market reports, the global market size for artificial intelligence robots is projected to reach $52.3 billion by 2024, with a substantial increase to $619 billion in 2025 and an anticipated growth to $322.6 billion by 2032. This exponential growth underscores the critical impact of automation on manufacturing processes, particularly in areas like automotive production and logistics.

In 2023, China's Ministry of Industry and Information Technology released the "Robot + Application Action Implementation Plan," emphasizing the advancement of smart manufacturing. The initiative aims to establish smart manufacturing demonstration factories and promote the typical application of industrial robots. Furthermore, the humanoid robot market is expected to see significant growth, with projections indicating a value of $23.73 billion by 2032 and a compound annual growth rate of 34.2% from 2024 to 2032. These trends highlight the ongoing transformation within traditional industries, showcasing how the integration of advanced robotics can lead to new levels of productivity and efficiency.

Key Statistics on Robot Adoption Rates in Global Manufacturing Sector

The global robotic process automation market is projected to expand significantly, with estimates predicting growth from

$22.58 billion in 2025 to

$72.64 billion by 2032. This represents a remarkable compound annual growth rate (CAGR) of

18.2%. Such growth reflects the increasing integration of robotics in manufacturing processes, underscoring the ongoing

transformation spurred by Industry 4.0 technologies.

Moreover, the Industry 4.0 market is anticipated to flourish, growing from

$130.9 billion in 2022 to an impressive

$377.33 billion by 2029, marking a CAGR of

16.3% during this period. The adoption of

digital twin technology is identified as a key driver of this expansion. By leveraging advanced

simulation designs and high-resolution modeling, manufacturers are now able to undertake precise manufacturing processes,

thereby unlocking innovative applications in product design and engineering. As these technologies mature, they will continue

to redefine operational efficiencies and overall industry standards in the manufacturing sector.

Impact of Automation on Workforce Dynamics and Job Evolution in Factories

The integration of industrial robots and automation technologies in manufacturing is reshaping workforce dynamics and driving significant job evolution in factories. As industries adopt advanced automation solutions, there is a clear trend towards a sophisticated skill set requirement. A systematic review indicates that by 2025, demographic shifts and technological advancements will necessitate a workforce that is adept at operating alongside these emerging technologies. The need for reskilling is paramount, with studies highlighting that nearly 85% of jobs will change due to AI and digital tools.

Manufacturers must now navigate a complex labor landscape characterized by the emerging skills gap. A recent report underscores that many current educational frameworks do not align with the skills required in automated environments. Employers are increasingly turning to strategic workforce planning to adapt, emphasizing the importance of a holistic talent strategy that prepares workers for an increasingly automated industry. Furthermore, as companies implement AI, the workplace hierarchies are being flattened, promoting a culture of collaboration that leverages both human and machine strengths.

In this evolving landscape, companies face the challenge of building a future-ready workforce capable of thriving amidst technological disruption. Reports indicate that firms embracing strategic reskilling initiatives and fostering adaptive work environments are not only enhancing productivity but also ensuring their resilience in the face of continuous change.

Emerging Trends in Robotics Technology and Their Implications for Future Manufacturing

The rapid advancement of robotics technology is poised to reshape the landscape of manufacturing industries significantly. According to a report by McKinsey, automation could potentially displace more than 20 million manufacturing jobs globally by 2030, yet concurrently, it is expected to create new roles that require advanced technical skills. This dual impact emphasizes the importance of adaptive workforce strategies in an increasingly automated environment.

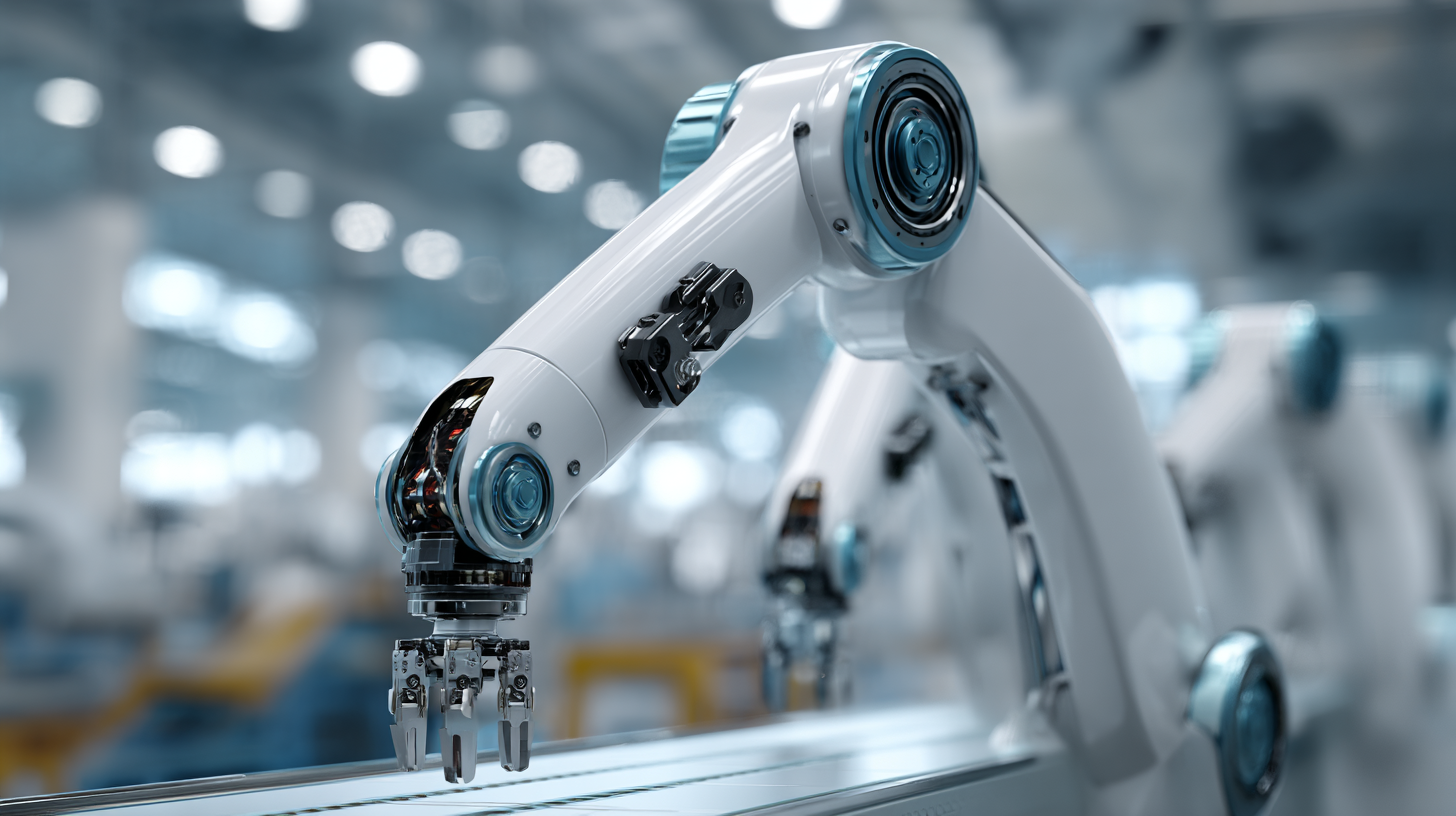

Emerging trends in robotics, such as collaborative robots (cobots) and artificial intelligence-driven systems, are enhancing productivity while ensuring safety in manufacturing workflows. A study by the International Federation of Robotics indicates that the global stock of industrial robots is projected to reach 5.6 million units by 2024, signifying a compound annual growth rate of around 13%. These developments not only streamline operations but also allow manufacturers to respond more swiftly to market changes and consumer demands, thus attracting a more tech-savvy workforce.

As industries embrace these innovations, the focus will increasingly shift toward continuous learning and skills development to harness the full potential of robotic integration.

Case Studies of Successful Robot Integration in Various Manufacturing Industries

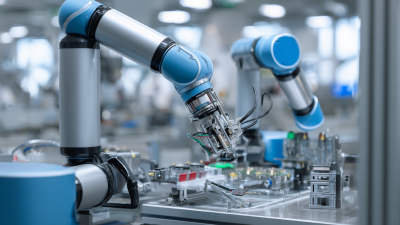

As manufacturing industries dive into the future, successful integration of industrial robots has become a key determinant of operational efficiency and productivity. One notable case is that of an automotive manufacturer that incorporated robotic arms on their assembly line. These robots enhanced precision in welding and painting processes, significantly reducing the margin of error and improving product quality. The introduction of advanced robotics not only streamlined assembly time but also allowed human workers to focus on complex tasks that require critical thinking and problem-solving, creating a more harmonious human-robot collaboration.

Another compelling example can be found in the electronics sector, where a leading company implemented collaborative robots, or cobots, in its production lines. These cobots are designed to work alongside human workers without safety barriers, enabling a more fluid workflow. They assist with repetitive tasks such as component placement and quality inspection, which has led to a substantial increase in production rates. The integration of robots not only minimizes labor costs but enhances worker safety and job satisfaction, highlighting the transformative impact of robotic technology on traditional manufacturing processes.

Related Posts

-

Exploring the Future of Palletizing Robots at the 138th China Import and Export Fair 2025

-

What Are the Advantages of Using Robotic Process Automation Tools

-

Transforming Logistics: Cobot Palletizers at the 138th Canton Fair 2025 – Industry Insights and Innovations

-

How to Harness the Power of AI Robots for Everyday Tasks

-

How to Enhance Manufacturing Efficiency with Cobot Robots in Your Business

-

Unleashing Digital Transformation: The Ultimate Guide to Robotic Process Automation Software

Smart Robotics brand movie

Watch video