Top Robotic Solutions to Transform Your Business in 2025

As we move closer to 2025, the integration of robotic solutions is set to redefine the landscape of business operations across various industries. According to a report by McKinsey, automation could potentially increase productivity by up to 40% in certain sectors, making robotic solutions not just an option, but a necessity for organizations aiming to remain competitive. The rise of artificial intelligence and machine learning will further enhance the capabilities of these solutions, leading to smarter, more efficient processes.

Moreover, a study from PwC estimates that up to 30% of jobs could be automated by the mid-2030s, signifying a transformative shift in the workforce. This evolution demands businesses to not only adopt robotic solutions for repetitive tasks but also to leverage them for complex problem-solving and decision-making processes. Companies that proactively implement these technologies will gain a strategic advantage, enabling them to streamline operations, reduce costs, and improve service delivery. Embracing robotic solutions is no longer just about keeping up; it is about thriving in an increasingly automated future.

Emerging Robotic Technologies Shaping Business Futures in 2025

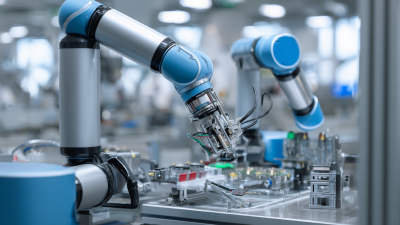

As we approach 2025, businesses are increasingly exploring how emerging robotic technologies can redefine their operations, improve efficiency, and drive innovation. Autonomous robots equipped with advanced AI algorithms are poised to revolutionize industries by automating repetitive tasks, allowing human workers to focus on more strategic endeavors. From manufacturing to logistics, these robots can enhance productivity through seamless integration with existing workflows, minimizing errors and optimizing output.

Moreover, advancements in collaborative robotics—cobots—are enabling a new era of human-robot interaction. These robots are designed to work alongside humans, enhancing capabilities rather than replacing them. In warehouses and production lines, cobots assist with tasks such as picking and packing while ensuring workplace safety. Furthermore, sectors like healthcare are witnessing the rise of robotic solutions that can perform surgeries with precision or provide elderly care, thus transforming traditional methods and improving service delivery. The fusion of robotics with data analytics and the Internet of Things (IoT) offers the potential for smarter business operations, driving decision-making processes and innovation in ways that were previously unimaginable.

Key Industries Benefiting from Robotic Automation Solutions

In 2025, robotic automation is poised to redefine various key industries, significantly enhancing operational efficiency and productivity. According to a report by McKinsey, the adoption of robots in manufacturing alone could increase global labor productivity by up to 30% by 2030. Sectors such as automotive and electronics are leading the charge, leveraging robotic solutions for tasks ranging from assembly to quality control. This shift not only streamlines processes but also reduces human error, thereby increasing overall output quality.

Moreover, the healthcare industry stands to gain immensely from robotic automation. A study by Deloitte projects that the integration of robotics in healthcare could save the sector over $40 billion annually by 2025. Automation can assist in surgeries, patient handling, and administrative tasks, allowing healthcare professionals to focus on more critical aspects of patient care. As hospitals and clinics invest in robotics, they improve patient outcomes while also addressing the pressing challenges of workforce shortages and rising operational costs. The transformative power of robots in industries such as manufacturing and healthcare is becoming increasingly evident, setting the stage for a more efficient future.

Impact of Robotics on Workforce Dynamics and Skill Requirements

As we approach 2025, the integration of robotic solutions is poised to significantly alter workforce dynamics across various sectors. The introduction of automation and robotics not only streamlines processes but also reshapes job roles and responsibilities. Traditional skill sets are becoming outdated as machines take over repetitive tasks. Consequently, employees must adapt by acquiring new competencies that complement robotic technology rather than compete against it. Workers will increasingly need to enhance their digital literacy, critical thinking, and problem-solving abilities to thrive in this evolving landscape.

Moreover, the shift towards robotics necessitates a focus on lifelong learning and reskilling initiatives. Organizations will need to invest in training programs that not only teach employees how to work alongside machines but also empower them to leverage new technologies creatively. This transition fosters a collaborative environment where human workers and robots coexist, maximizing productivity and innovation. As businesses embrace these technological advancements, the emphasis on soft skills, such as communication and teamwork, will also rise, as these capabilities remain vital in a hybrid workforce environment.

Impact of Robotics on Workforce Dynamics and Skill Requirements in 2025

Best Practices for Implementing Robotic Solutions in Businesses

Implementing robotic solutions in a business setting involves best practices that ensure optimal integration and successful outcomes. First, organizations should start by assessing their workflows to identify repetitive tasks that can benefit from automation. This could range from data entry to customer service inquiries. By pinpointing these processes, businesses can tailor robotic solutions to meet their specific needs, enhancing efficiency and accuracy across operations.

Training and reskilling employees is another crucial aspect of successfully adopting robotic solutions. Workers should be involved in the implementation process to reduce apprehension about new technologies. Providing comprehensive training not only empowers employees to leverage robotic tools effectively but also fosters a culture of innovation within the organization. Engaging staff through workshops and hands-on experience can ease the transition and encourage a collaborative atmosphere where humans and robots work side by side.

Lastly, continuous evaluation and feedback mechanisms are vital. Once robots are integrated into business processes, companies must regularly monitor the performance and impact of these solutions. Gathering feedback from employees who interact with these technologies can provide insights into areas for improvement and help refine the systems over time, ensuring that robotic solutions evolve alongside business goals and market demands.

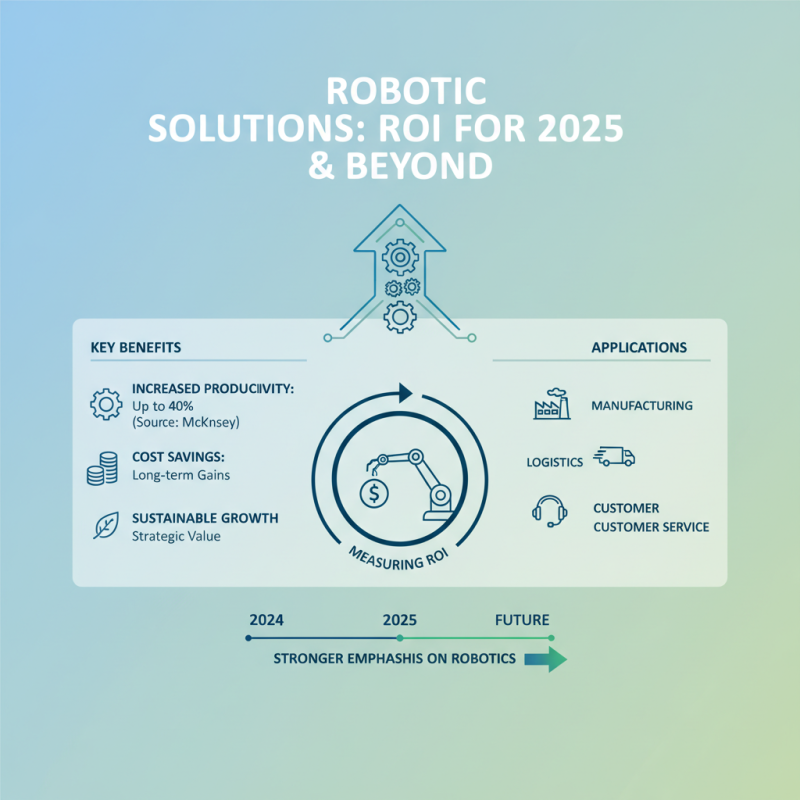

Measuring the ROI of Robotic Investments for Sustainable Growth

As businesses look towards 2025, the emphasis on robotic solutions is stronger than ever, particularly in terms of measuring the return on investment (ROI) these technologies can generate for sustainable growth. According to a recent report from McKinsey, automation and robotics could potentially increase productivity by up to 40%, suggesting that the upfront costs associated with robotic investments can be turned into long-term gains. By analyzing the cost-saving benefits, businesses can determine the strategic value of deploying automation in areas such as manufacturing, logistics, and customer service.

An additional aspect to consider is the predictive maintenance capabilities offered by robotic solutions. The market for predictive maintenance is expected to grow to $12.3 billion by 2025, as per Data Bridge Market Research. This indicates that businesses leveraging robotics can not only reduce downtime and maintenance costs but also enhance operational efficiency. Organizations that effectively measure these impacts and align their robotic investments with key performance indicators (KPIs) can expect a clearer path to sustainable growth, validating their investment through quantifiable improvements in operational efficiency and productivity metrics.

Related Posts

-

How to Enhance Manufacturing Efficiency with Cobot Robots in Your Business

-

2025 Top 10 Robotic Solutions Revolutionizing Automation with Over 50 Percent Industry Growth

-

Exploring the Future of Robotics Engineering in Everyday Life

-

Revolutionizing Supply Chains: How Warehouse Robots Are Shaping the Future of Logistics

-

Top 10 Robotics Companies Leading the Future of Automation and Innovation

-

Why Robotics Engineering is the Future of Innovation and Technology

Smart Robotics brand movie

Watch video