Top 10 Robotic Arm Applications Transforming Industries You Must Know

In today's rapidly evolving technological landscape, the integration of robotic arms into various industries is not just a trend but a transformative force reshaping how businesses operate. According to Dr. Emily Chen, a leading expert in robotics engineering, "Robotic arms are revolutionizing manufacturing and beyond, providing precision, efficiency, and the ability to handle tasks that were once deemed too complex or dangerous for human workers." This statement encapsulates the essence of robotic arms, which are becoming indispensable across multiple sectors, from manufacturing and healthcare to agriculture and logistics.

As industries continue to seek innovative solutions to enhance productivity and reduce operational costs, the adoption of robotic arms has surged. These versatile machines are capable of performing a wide range of functions, including assembly, welding, painting, and even intricate surgical procedures. With advancements in artificial intelligence and machine learning, the capabilities of robotic arms are expanding, enabling them to work alongside human operators in increasingly collaborative environments. The transformative potential of these technologies is not only enhancing operational efficiency but also redefining the workforce's role, paving the way for a smarter and safer industrial future.

In this article, we will explore the top ten applications of robotic arms that are making significant impacts across various industries, demonstrating how they are not merely tools but essential partners in today's business landscape.

Top 10 Robotic Arm Applications Transforming Industries You Must Know

Robotic arms have revolutionized various industries by enhancing efficiency, accuracy, and safety. In manufacturing, these versatile machines automate repetitive tasks such as assembly, welding, and painting, leading to increased productivity. The precision of robotic arms significantly minimizes human error, ensuring a higher quality of output and allowing human workers to focus on more complex and creative tasks.

In healthcare, robotic arms are transforming surgical procedures. Their ability to perform intricate movements with precision allows for minimally invasive surgeries, resulting in quicker recovery times for patients. Additionally, robotic arms assist in rehabilitation therapy, providing support and guided movements for patients recovering from injuries.

Tips: When considering the implementation of robotic arms in your industry, it is essential to evaluate the specific tasks that would benefit most from automation. Start small and gradually scale up the use of robotic technology to ensure a smooth transition and to identify areas for improvement. Training for staff is also crucial to maximize the potential of robotic systems, ensuring that they can oversee and maintain these advanced tools effectively.

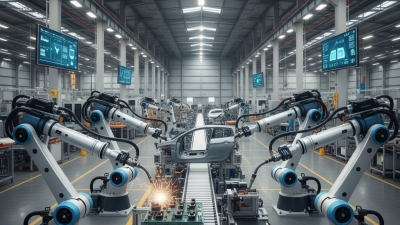

Revolutionizing Manufacturing: The Role of Robotic Arms in Automation

In today's fast-paced manufacturing landscape, robotic arms have emerged as pivotal players in the automation revolution. These sophisticated machines offer precision and efficiency that human hands simply cannot match. By integrating robotic arms into production lines, manufacturers can achieve higher output rates while minimizing errors. This level of automation not only accelerates processes but also enables companies to focus their human resources on more strategic tasks, thereby fostering innovation and creativity.

Moreover, the adaptability of robotic arms allows them to perform a variety of functions, from assembly and welding to painting and packaging. This versatility makes them indispensable in industries ranging from automotive to electronics. As technology advances, the functionality of robotic arms continues to expand, with features like artificial intelligence and machine learning enhancing their ability to learn and adapt in real time. This evolution not only increases productivity but also ensures consistency in quality, transforming manufacturing into a more streamlined and reliable endeavor.

Top 10 Robotic Arm Applications Transforming Industries

| Application | Industry | Key Benefits | Example Task |

|---|---|---|---|

| Assembly | Manufacturing | Increased speed and precision | Joining parts together |

| Welding | Automotive | Improved quality and safety | Joining metal structures |

| Pick and Place | Logistics | Enhances efficiency in packaging | Sorting products |

| Painting | Manufacturing | Uniform application and reduced waste | Coating products |

| Material Handling | Manufacturing | Reduced labor costs and increased safety | Moving heavy materials |

| Inspection | Electronics | Enhanced accuracy in quality control | Checking for defects |

| Soldering | Electronics | Improved speed and reliability | Connecting components on a circuit board |

| Packaging | Food and Beverage | Higher productivity and shelf life | Filling and sealing products |

| Bending | Manufacturing | Precision and consistency in shapes | Bending metal sheets |

| 3D Printing | Additive Manufacturing | Flexibility in designs | Creating prototypes |

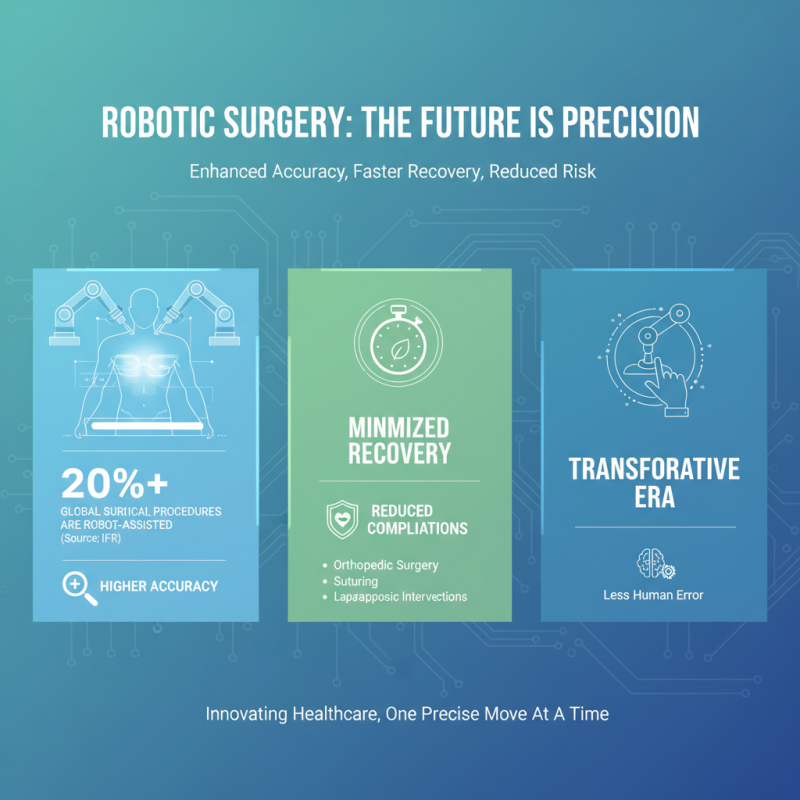

Improving Precision: Robotic Arms in Surgery and Medical Applications

Robotic arms have significantly enhanced the precision and effectiveness of surgical procedures, marking a transformative era in the medical field. According to a report by the International Federation of Robotics, the adoption of surgical robots has surged, with over 20% of surgical procedures globally now incorporating robotic assistance. These advanced systems allow surgeons to perform intricate operations with higher accuracy, reduced recovery times, and minimized risks of complications. For instance, procedures such as orthopedic surgeries, suturing, and laparoscopic interventions have seen a notable decline in human error due to the precision offered by robotic arms.

In addition to surgical applications, robotic arms are also being utilized in rehabilitation therapy. A study published in the Journal of NeuroEngineering and Rehabilitation found that robotic-assisted therapy significantly improved motor function and recovery rates in stroke patients. These robots provide consistent and adjustable support, enabling patients to engage in repetitive motions critical for their rehabilitation process.

Tips: When considering robotic arms for medical applications, focus on their adaptability and ease of integration into existing workflows. Ensure that your team is trained adequately to maximize the potential of these technologies. Regularly assess the performance of robotic systems to stay updated on best practices, and always prioritize patient safety in every procedure.

Enhancing Efficiency: Robotic Arms in Logistics and Supply Chain

Robotic arms are revolutionizing logistics and supply chain management by enhancing efficiency and productivity. According to a report from McKinsey, automating warehouse tasks can lead to productivity increases of 25% to 30%. Such automation allows for the swift handling of goods, which is critical in an era where consumer expectations for speed and accuracy are at an all-time high. By using robotic arms for tasks such as picking, packing, and sorting, companies can significantly reduce the time taken to process orders, minimizing delays and improving overall customer satisfaction.

In addition to increasing speed, robotic arms contribute to a safer working environment. The International Federation of Robotics reports that the deployment of robotic technologies in logistics can reduce workplace accidents by up to 50%. This is especially important in environments where heavy lifting and repetitive motions are common, as robotic arms can take over these physically demanding tasks. With the labor market tightening, integrating robotic arms into supply chains not only addresses the need for efficiency but also helps in mitigating the risks associated with manual labor, proving to be a strategic investment for businesses looking to thrive in a competitive landscape.

Advancing Agriculture: The Impact of Robotic Arms on Farming Practices

The integration of robotic arms into agricultural practices is revolutionizing the way food is produced and harvested. According to a report by the International Federation of Robotics, the use of robotics in agriculture is expected to grow significantly, with projections indicating a compound annual growth rate of over 20% from 2020 to 2025. This surge is driven by the increasing need for efficiency and sustainability in farming operations, as the global population continues to rise and arable land diminishes.

Robotic arms are transforming tasks such as planting, harvesting, and packaging, making them faster and more precise. For instance, advancements in precision agriculture allow for the accurate application of fertilizers and pesticides, minimizing waste and environmental impact. A report from MarketsandMarkets estimates that precision agriculture could reduce costs by up to 20%, showcasing not just an improvement in productivity but also a pathway toward more sustainable farming practices. In addition, these robotic systems help alleviate labor shortages faced by farmers, ensuring that crops are harvested promptly and efficiently, ultimately contributing to food security in an evolving agricultural landscape.

Impact of Robotic Arms on Farming Practices

Conclusion

Robotic arms are revolutionizing various industries by enhancing automation, precision, and efficiency. In manufacturing, robotic arms streamline production lines, allowing for faster and more accurate assembly processes. In the medical field, these advanced tools are used in surgeries, improving precision and reducing recovery times for patients.

Moreover, robotic arms significantly enhance logistics and supply chain management by automating tasks and optimizing inventory handling. In agriculture, they are transforming farming practices through automated planting, harvesting, and monitoring, leading to increased yields and reduced labor costs. Lastly, in construction, robotic arms are being utilized for building and infrastructure projects, improving both safety and productivity on job sites. Overall, the versatility of robotic arms continues to propel innovation across multiple sectors.

Related Posts

-

10 Tips for Choosing the Right Industrial Robotic Arm for Your Business

-

2025 Top 10 Robotic Solutions Revolutionizing Automation with Over 50 Percent Industry Growth

-

Revolutionizing Supply Chains: How Warehouse Robots Are Shaping the Future of Logistics

-

Why Industrial Robotic Arms Are Revolutionizing Modern Manufacturing Processes

-

10 Proven Benefits of Robotic Process Automation Software for Boosting Business Efficiency

-

Exploring the Future of Online Robots in Everyday Life and Digital Interactions

Smart Robotics brand movie

Watch video