Revolutionizing Supply Chains: How Warehouse Robots Are Shaping the Future of Logistics

As the logistics industry continues to evolve, the integration of warehouse robots is revolutionizing supply chains across the globe. According to a report by the International Federation of Robotics, the number of warehouse robots is expected to exceed 1.3 million units by 2025, signifying a profound shift in operational capabilities. These robots are not only enhancing efficiency but also reducing operational costs, with studies indicating that automation in warehouses can lead to a 30% increase in productivity and a substantial decrease in order fulfillment times.

Furthermore, the market for logistics robots is projected to reach $37.4 billion by 2025, indicating a robust demand for automation solutions in the sector. As companies seek to optimize their logistics operations, the growing reliance on warehouse robots presents a strategic advantage, enabling businesses to meet rising consumer expectations while navigating an increasingly complex supply chain landscape.

Impact of Warehouse Robots on Operational Efficiency in Logistics

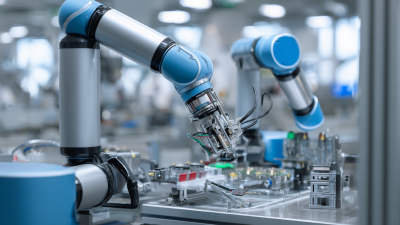

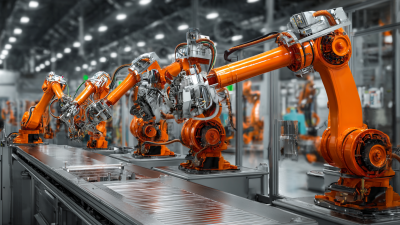

The integration of warehouse robots into supply chains is transforming logistics operations by significantly enhancing operational efficiency. These automated systems streamline various tasks, such as inventory management, order picking, and sorting. By reducing the reliance on manual labor, companies can minimize errors and improve speed, resulting in faster order fulfillment. Robots equipped with advanced sensors and AI algorithms can navigate complex warehouse environments, optimizing their movements and ensuring that goods are handled with precision.

Moreover, the deployment of warehouse robots allows businesses to address labor shortages and rising operational costs. With the ability to operate continuously without the need for breaks, robots increase throughput and maintain productivity levels during peak periods. This not only boosts operational capacity but also allows human workers to focus on more complex, strategic tasks, fostering a more innovative working environment. As a result, the enhanced collaboration between human employees and robotic systems paves the way for a more adaptive and resilient logistics framework, prepared to meet the demands of an ever-evolving market.

Emerging Technologies in Automated Warehousing: Trends and Future Prospects

The rise of emerging technologies in automated warehousing is reshaping the logistics landscape, driving efficiency and accuracy to unprecedented levels. With the integration of artificial intelligence, machine learning, and the Internet of Things (IoT), warehouses are evolving into smart operations where robotics seamlessly coordinate with inventory management systems. These technologies enable real-time data analytics, providing companies with valuable insights into inventory flows, order processing, and demand forecasting.

Trends such as autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) are becoming integral to warehouse operations. These robots not only enhance order picking and sorting efficiencies but also reduce operational costs and enhance worker safety by taking over repetitive and hazardous tasks. As these robotic solutions continue to advance, the future of logistics promises further innovations, including enhanced collaboration between human workers and robots, leading to a more streamlined and productive supply chain ecosystem.

Warehouse Robots Adoption Trends (2020-2023)

This chart illustrates the growing trend of warehouse robot adoption from 2020 to 2023. It showcases a significant increase in adoption rates over the years, highlighting the transformation in logistics and supply chain management through automation.

Cost Savings and ROI: Quantifying the Benefits of Warehouse Robotics

Warehouse robotics is transforming the logistics landscape by delivering substantial cost savings and improved return on investment (ROI) for businesses. With automation in warehouses, organizations can streamline operations, minimize labor costs, and enhance efficiency. Recent insights reveal that automated systems not only reduce the time taken for picking and packing but also significantly lower error rates, leading to decreased operational expenditures. As supply chain resilience gains importance, the shift towards robotic solutions becomes a critical strategy to ensure competitiveness in a fast-evolving market.

Tips for Maximizing ROI from Warehouse Robotics:

- Evaluate Total Cost of Ownership: Consider all costs associated with warehouse robotics, including initial investment, maintenance, and integration expenses, to gain a clear picture of long-term ROI.

- Focus on Data Analytics: Leverage data collected from robotic systems to enhance decision-making processes, identify inefficiencies, and optimize inventory management.

- Measure Performance Metrics: Regularly assess productivity and accuracy improvements post-automation to quantify benefits, ensuring that you achieve the desired ROI.

Integrating Robotics with Existing Supply Chain Systems: Challenges and Solutions

The integration of robotics into existing supply chain systems presents a myriad of challenges that organizations must navigate. One significant hurdle is the

interoperability between robotic systems and traditional warehouse management software. Many existing systems were not designed with automation in mind, which can lead to inefficiencies during the implementation process. Ensuring that robots can communicate seamlessly with legacy software requires

careful planning and potentially costly upgrades, which may deter some companies from pursuing full automation.

Another challenge lies in workforce adaptation. As warehouses introduce robotic technologies, employees may need to transition to new roles that require different skill sets, such as overseeing automated processes or managing data analytics. This shift can result in resistance among staff, highlighting the need for comprehensive training programs. Companies must invest in

change management strategies that promote a positive culture around automation, facilitating smoother transitions while alleviating employee concerns about job displacement. Embracing these challenges with strategic foresight will not only enhance operational efficiency but also empower employees in a tech-driven future.

The Role of AI and Machine Learning in Enhancing Warehouse Robotics Performance

The integration of AI and machine learning into warehouse robotics is significantly transforming logistics, enhancing operational efficiency, and optimizing resource management. According to a report by the McKinsey Global Institute, warehouse automation has the potential to boost productivity by 20-25%, largely due to advancements in AI-driven decision-making processes. These technologies enable robots to adapt to real-time data, allowing for improved inventory management and streamlined workflows.

Machine learning algorithms are increasingly being employed to facilitate predictive analytics in warehouse environments. A study by Gartner highlights that by 2025, 75% of organizations will use AI and machine learning in their supply chain processes, resulting in smarter inventory distribution and reduced operational costs. Robots equipped with AI can learn from previous tasks, allowing them to make informed decisions about task prioritization and route optimization, which is essential in maintaining the fast-paced demands of modern logistics. As these technologies continue to evolve, they are set to revolutionize how warehouse operations function, making them more effective and resilient.

Related Posts

-

Exploring the Future of Robotics Engineering in Everyday Life

-

How to Enhance Manufacturing Efficiency with Cobot Robots in Your Business

-

Revolutionizing Logistics: How Warehouse Automation Robots are Shaping the Future of Supply Chains

-

The Future of Work How Industrial Robots are Transforming Manufacturing Industries

-

Top 5 Robotics Companies Driving $110 Billion Global Market Growth in 2023

-

What Are the Advantages of Using Robotic Process Automation Tools

Smart Robotics brand movie

Watch video