Revolutionizing Efficiency: The Future of Packaging Robots in Smart Warehousing

As industries continue to adapt to the rapid evolution of technology, the integration of packaging robots in smart warehousing has emerged as a game-changer in enhancing operational efficiency. According to a report by Allied Market Research, the global packaging robots market is projected to reach $9.6 billion by 2027, growing at a CAGR of 12.2% from 2020. This significant growth underscores the increasing reliance on automation to streamline logistics and distribution processes. Packaging robots are not only optimizing packing speed but also improving accuracy and reducing labor costs, making them an essential component in modern supply chains. In this context, understanding the future potential and best practices for implementing packaging robots becomes crucial for businesses aiming to innovate and maintain a competitive edge in an increasingly automated landscape.

The Role of AI in Enhancing Packaging Robots for Smart Warehousing

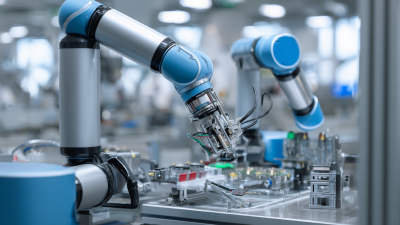

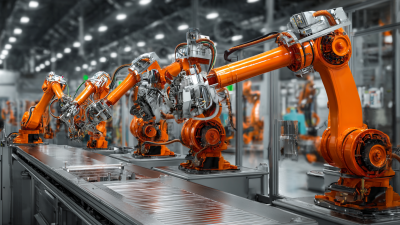

As the demand for seamless logistics solutions surges, the role of AI in enhancing packaging robots within smart warehousing is becoming increasingly significant. With advancements in robotics, warehouses can now integrate sophisticated AI algorithms that enable these machines to efficiently manage various operations. From sorting and packing to inventory management, AI-driven packaging robots are revolutionizing the warehousing landscape, paving the way for unparalleled efficiency and accuracy.

Tips: To maximize efficiency, businesses should invest in continuous training for both robots and human operators, ensuring they can work in tandem. Additionally, companies should explore data analytics to gain insights into inventory trends, allowing for smarter automation solutions.

The logistics industry stands on the brink of a major transformation, driven by AI and automation technologies. Notably, the adoption of intelligent systems not only addresses labor shortages but also streamlines processes, leading to reduced operational costs. Embracing these innovations positions companies to meet the evolving demands of the market while enhancing overall productivity.

Tips: It's essential to prioritize scalable technology solutions that can adapt as your operations grow. Regularly reviewing and upgrading your automation systems can keep your warehouse ahead of industry trends.

Analyzing Cost Savings: How Packaging Robots Improve Warehouse Efficiency

The integration of packaging robots into smart warehousing marks a significant stride towards operational efficiency. As businesses increasingly rely on automation, these robots are streamlining the packaging process, significantly reducing labor costs while enhancing output. By automating repetitive tasks, companies can redirect human resources towards more complex activities that require creative solutions, leading to an overall improvement in productivity.

Tips for implementing packaging robots effectively include selecting the right technology that aligns with your warehouse needs and training staff to work alongside these systems smoothly. Adopt a phased approach to integration, allowing staff to adjust and providing sufficient time for troubleshooting. Regular maintenance, along with real-time data monitoring, ensures that robots function optimally, minimizing downtimes and maximizing efficiency.

Furthermore, employing packaging robots not only contributes to cost savings but also fosters a greener operation. These machines can optimize material usage, reducing waste and energy consumption. As businesses increasingly emphasize sustainability, adopting robotic solutions opens new pathways for eco-friendly practices within the warehousing sector, proving that efficiency and environmental responsibility can go hand in hand.

Revolutionizing Efficiency: The Future of Packaging Robots in Smart Warehousing

| Warehouse Size (sq ft) | Number of Robots | Annual Labor Cost (USD) | Annual Operational Cost (USD) | Cost Savings (%) | Efficiency Improvement (%) |

|---|---|---|---|---|---|

| 50,000 | 10 | $300,000 | $50,000 | 20% | 30% |

| 100,000 | 20 | $600,000 | $80,000 | 30% | 40% |

| 200,000 | 50 | $1,200,000 | $150,000 | 35% | 50% |

Integrating IoT Technology: A Game Changer for Packaging Automation

The integration of IoT technology into packaging automation is poised to redefine the landscape of smart warehousing. As the world moves towards heightened efficiency, IoT-enabled packaging robots are essential in creating a seamless workflow. These robots not only streamline the packing process but also gather real-time data that can optimize both inventory management and supply chain operations. The ability to monitor conditions and product statuses remotely allows for quick decision-making, reducing delays and improving overall productivity.

Moreover, the evolution of AI-assisted robots marks a significant advancement in the automation of packaging. With capabilities such as automated picking and packing, these intelligent systems can adapt to diverse product specifications and fluctuating demand. This versatility not only ensures greater accuracy and efficiency but also supports sustainable practices by minimizing waste. The convergence of IoT and robotics is clearly a game changer, empowering businesses to build smarter, more responsive warehousing infrastructures that can keep pace with the rapid shifts in consumer expectations and market dynamics.

Revolutionizing Efficiency in Smart Warehousing

Case Studies: Successful Implementation of Packaging Robots in Warehousing

In recent years, companies have increasingly turned to packaging robots as a means to enhance operational efficiency in smart warehousing.

One notable case is the implementation of automated packaging systems by a major e-commerce retailer. By integrating robotic arms that handle packing, sorting, and labeling, the retailer significantly reduced the time required for order fulfillment. This not only accelerates delivery times but also lowers labor costs, allowing the workforce to focus on higher-value tasks.

Another compelling example comes from a logistics company that adopted flexible robotic systems capable of adapting to various packaging needs. With advanced machine learning algorithms, these robots optimize packaging based on product dimensions and weight, minimizing material waste and improving inventory management. As a result, the company has reported a substantial increase in throughput and a decrease in packaging-related errors, showcasing the transformative potential of robotics in the warehousing sector.

Future Trends: The Evolution of Packaging Robots and Industry Projections

The evolution of packaging robots has been significantly influenced by advancements in artificial intelligence and automation technologies. As smart warehousing systems become increasingly integrated with Internet of Things (IoT) devices, the demand for more intelligent and adaptable packaging solutions is on the rise. Modern packaging robots are now equipped with machine learning algorithms that allow them to adjust their operations in real-time based on varying product specifications and environment conditions. This adaptability not only increases efficiency but also minimizes errors in packaging processes.

Looking ahead, the industry projections indicate a substantial growth in the deployment of packaging robots within warehouses. Experts predict that by the end of the decade, a significant percentage of packaging tasks will be automated, leading to reduced labor costs and improved overall productivity. Furthermore, with the shift towards sustainable practices, future packaging robots are likely to be designed with eco-friendly materials and processes in mind. This convergence of technology and sustainability will shape the future of smart warehousing, paving the way for a more efficient and responsible logistics landscape.

Related Posts

-

How to Enhance Manufacturing Efficiency with Cobot Robots in Your Business

-

Unlocking the Future of Work with Robotic Process Automation for Everyday Tasks

-

What Are the Advantages of Using Robotic Process Automation Tools

-

How to Harness the Power of AI Robots for Everyday Tasks

-

Unleashing Digital Transformation: The Ultimate Guide to Robotic Process Automation Software

-

The Future of Work How Industrial Robots are Transforming Manufacturing Industries

Smart Robotics brand movie

Watch video