What is a Packaging Robot and How It Revolutionizes the Packaging Industry

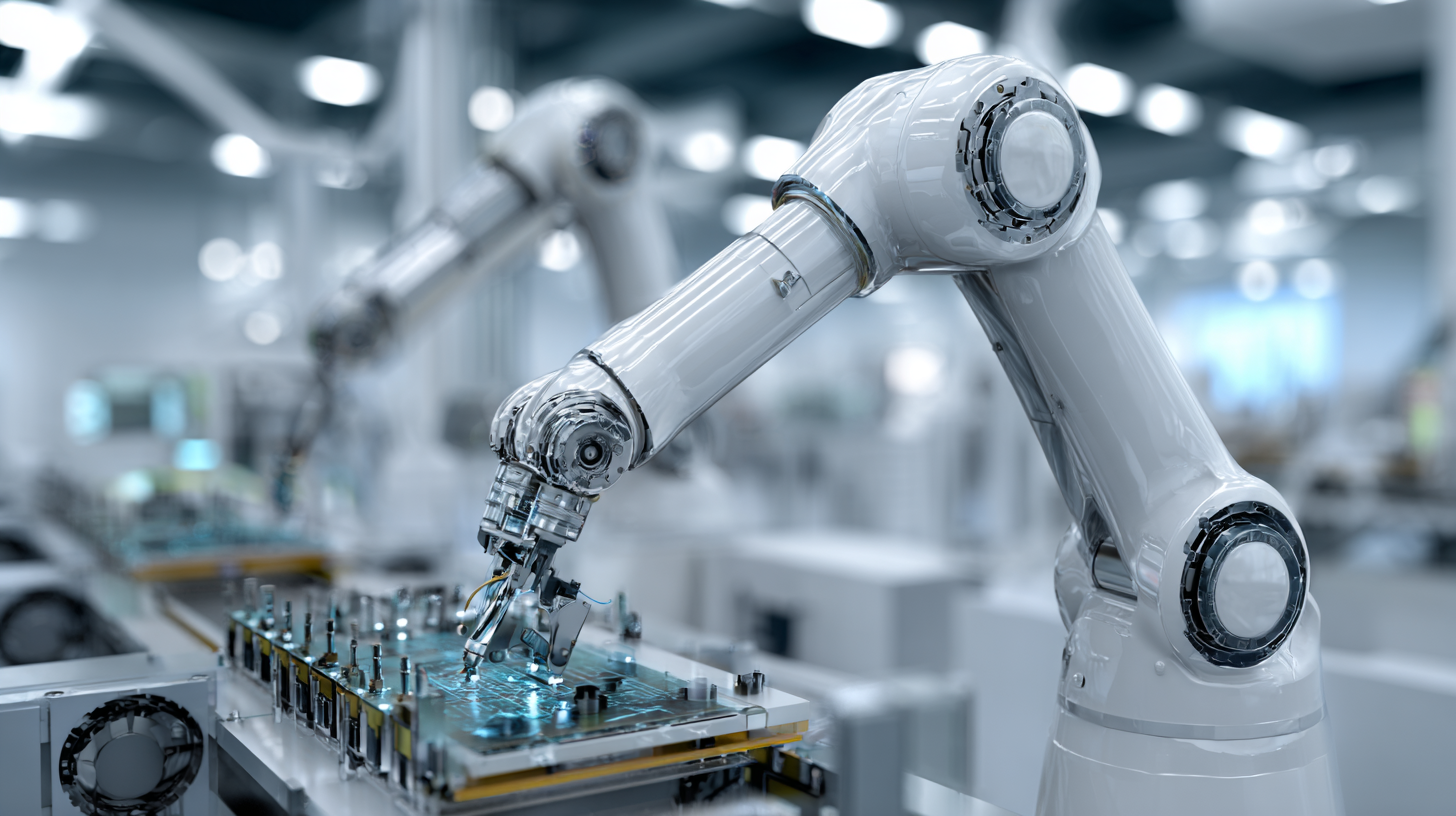

In the ever-evolving landscape of industrial automation, packaging robots have emerged as a game-changer in the packaging industry. As companies strive for greater efficiency and precision, the integration of robotic technology into packaging processes is not just a trend but a necessity. According to John Smith, a leading expert in robotic automation, “Packaging robots are transforming the way we think about efficiency and scalability in production lines.” This statement encapsulates the essence of how these innovative machines are reshaping traditional packaging methodologies.

As industries face increasing demands for faster production rates and higher quality assurance, packaging robots provide a solution that combines advanced technologies with unparalleled flexibility. These machines are adept at handling a variety of tasks, from sorting and packing products to palletizing, thus reducing human error and labor costs. The adaptability of packaging robots allows them to be implemented in diverse sectors, further solidifying their importance within the industry.

Not only do packaging robots improve operational efficiency, but they also enhance workplace safety by taking over repetitive and physically taxing tasks. As businesses continue to explore automation, the influence of packaging robots will undoubtedly grow, revolutionizing how products are packed and shipped worldwide. The evolution of this technology marks a significant milestone in the journey towards smarter, more efficient industrial processes.

The Definition and Functionality of Packaging Robots in Modern Manufacturing

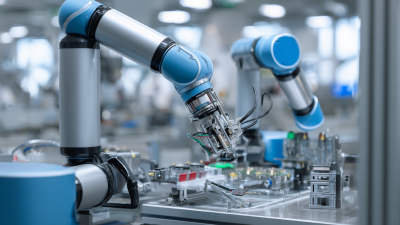

In modern manufacturing, packaging robots play a crucial role in enhancing efficiency and accuracy. Defined as automated machines designed to handle, package, and seal products, these robots significantly reduce labor costs while increasing productivity. According to a report by Research and Markets, the global packaging robot market is projected to grow at a CAGR of 12.3% from 2021 to 2026, highlighting the increasing reliance on automation in the industry. This trend is driven by the need for faster packaging processes and the ability to handle a diverse range of products without compromising quality.

The functionality of packaging robots varies from basic tasks like sorting and counting to more complex actions such as carton packing and palletizing. Advanced models integrate artificial intelligence and machine learning, allowing them to adapt to different packaging requirements and optimize workflows. In fact, a study from the International Federation of Robotics shows that companies utilizing packaging robots experience a 25% reduction in packaging material waste, a critical factor in today’s sustainability-focused market. As the demands for efficiency and precision in packaging solutions continue to rise, the adoption of packaging robots is set to revolutionize the packaging industry further.

What is a Packaging Robot and How It Revolutionizes the Packaging Industry

| Dimension | Description | Impact on Industry |

|---|---|---|

| Efficiency | Increased speed of packaging processes. | Shorter production cycles and reduced operational costs. |

| Precision | Robust automation leads to consistent packing sizes and placements. | Minimized waste and improved product quality. |

| Flexibility | Adaptability to various packaging types and products. | Enhanced ability to respond to market changes. |

| Labor savings | Reduction in manual labor for repetitive tasks. | Lowered labor costs and increased workforce satisfaction. |

| Safety | Decrease in workplace accidents related to packaging tasks. | Creating a safer working environment. |

Key Statistics on Packaging Robot Adoption Across Various Industries

The adoption of packaging robots is reshaping the packaging industry, driven by rapid advancements in technology and increasing demand for efficiency. According to industry reports, the automated packaging solutions market is projected to reach USD 162.2 billion by 2035, with a remarkable compound annual growth rate (CAGR) of 7.2% from 2025 to 2035. This growth is largely influenced by the integration of artificial intelligence (AI) technologies such as machine learning, computer vision, and predictive analysis in packaging processes, leading to enhanced speed and accuracy.

Key statistics reveal that various industries are increasingly adopting packaging robots to optimize their logistics and supply chain management. A recent analysis highlights the significant impact of robotics on digital logistics, showing that an integrated approach using hardware robots can streamline fulfillment processes, reduce operational costs, and improve overall productivity. The ongoing evolution of robotic training and capabilities further signifies the necessity for continued research and development in this field, ensuring packaging robots can meet future demands effectively.

The Impact of Packaging Robots on Efficiency and Productivity Metrics

Packaging robots have become a transformative force in the packaging industry, significantly enhancing efficiency and productivity metrics. By automating repetitive tasks such as sorting, packing, and palletizing, these robots reduce the time required for packaging processes. This increased speed not only expedites production lines but also minimizes human error, leading to more consistent and reliable output. As a result, companies can scale their operations without compromising on quality, allowing them to meet growing consumer demands effectively.

Furthermore, the integration of packaging robots allows businesses to allocate their human workforce to more complex and strategic tasks. This shift leads to higher employee satisfaction and better utilization of skills, ultimately driving innovation within the organization. The data-driven capabilities of these robots also facilitate real-time monitoring of production metrics, enabling companies to identify bottlenecks and optimize workflows dynamically. Overall, the adoption of packaging robots plays a crucial role in fostering a more efficient and productive operational environment in the packaging industry.

Impact of Packaging Robots on Efficiency and Productivity Metrics

Cost-Benefit Analysis: Comparing Traditional Packaging Methods vs. Robotics

The integration of robotics into the packaging industry presents a transformative shift in operational efficiency and cost-effectiveness. A comparative analysis indicates that traditional packaging methods often involve labor-intensive processes that can lead to higher error rates and increased operational costs. In contrast, robotic solutions deliver superior accuracy, repeatability, and speed, leading to a significant reduction in labor costs—estimates suggest up to 30% savings can be realized through automation.

Moreover, investment in robotics technology is on the rise, with the global AI in Packaging market expected to reach substantial figures by 2035, driven by advances in machine learning, natural language processing, and predictive analysis. Companies are increasingly adopting these technologies to streamline their logistics and supply chain management processes.

Tips: When considering a transition to robotic packaging, companies should perform a detailed cost-benefit analysis to assess potential savings versus initial investment. Staying updated on emerging trends in robotic technology will also ensure that businesses remain competitive. Finally, investing in employee training on how to work alongside robots can enhance overall operational efficiency.

Future Trends: Emerging Technologies in Packaging Automation and Robotics

As the packaging industry evolves, emerging technologies in automation and robotics are playing a pivotal role in enhancing efficiency and responsiveness. According to a report by Smithers Pira, the global market for packaging automation is projected to reach $70 billion by 2025. This growth can be attributed to advancements in robotics that allow for increased precision and speed while reducing labor costs. Automated packaging solutions are not only faster but also improve consistency, which is critical for brands aiming to maintain quality assurance.

Moreover, Industry 4.0 technologies, such as IoT and artificial intelligence, are becoming integral to packaging processes. A study by McKinsey indicates that companies utilizing AI in their operations can increase productivity by 20-25%. Robotics equipped with AI capabilities can analyze production patterns and adjust processes in real-time, optimizing workflows and minimizing downtime. As production demands shift rapidly due to consumer preferences, these smart systems empower manufacturers to be more agile, ensuring they stay competitive in a fast-paced market. This transformative shift underscores a future where packaging robots will not only dominate production lines but also streamline entire supply chains.

Related Posts

-

Revolutionizing Efficiency: The Future of Packaging Robots in Smart Warehousing

-

How to Enhance Manufacturing Efficiency with Cobot Robots in Your Business

-

Unlocking the Future of Work with Robotic Process Automation for Everyday Tasks

-

Transforming Logistics: Cobot Palletizers at the 138th Canton Fair 2025 – Industry Insights and Innovations

-

10 Proven Benefits of Robotic Process Automation Software for Boosting Business Efficiency

-

Future of Warehouse Robots at China's 138th Canton Fair 2025 Industry Insights and Market Growth Trends

Smart Robotics brand movie

Watch video