Why Industrial Robotic Arms Are Revolutionizing Modern Manufacturing Processes

In recent years, the manufacturing landscape has undergone a dramatic transformation, largely driven by advancements in technology. At the forefront of this revolution are industrial robotic arms, which have redefined efficiency and precision in manufacturing processes. According to a report by the International Federation of Robotics (IFR), the global sales of industrial robots reached nearly 380,000 units in 2020, reflecting a market growth of approximately 10% despite the challenges posed by the pandemic. This surge in adoption showcases how businesses now recognize the value of integrating industrial robotic arms into their operations to enhance productivity and maintain competitive advantages.

Moreover, as industries move towards automation, the demand for skilled labor is evolving. A study from McKinsey & Company predicts that by 2030, up to 70 million jobs may be affected by automation technologies, highlighting the significance of industrial robotic arms in bridging the labor gap. These systems not only elevate production rates but also improve quality control and reduce human error, promising a future where manufacturing processes are more resilient and adaptable. As companies increasingly leverage these innovations, understanding how to implement industrial robotic arms effectively becomes essential for thriving in the modern manufacturing era.

How to Understand the Fundamentals of Industrial Robotic Arms

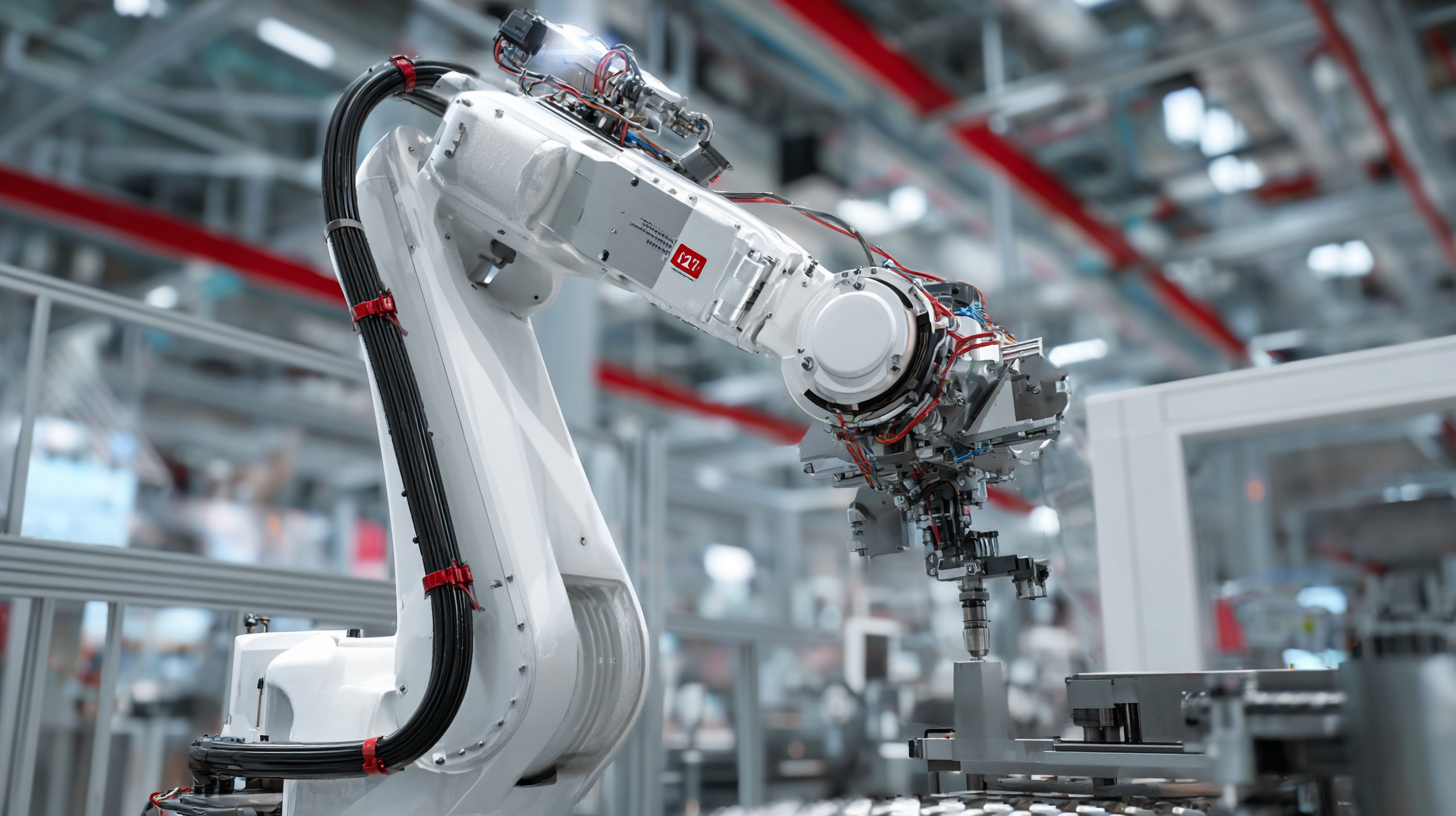

Industrial robotic arms are transforming modern manufacturing by enhancing efficiency and precision. To understand their fundamentals, one must first comprehend their structure and operation. Typically, these robotic arms consist of joints and links, mimicking the movement of a human arm. The joints might be rotary or linear, allowing the robot to perform a wide variety of tasks, from welding and painting to assembly and packaging. This versatility makes them essential in manufacturing environments where repetitive and precise operations are crucial.

Industrial robotic arms are transforming modern manufacturing by enhancing efficiency and precision. To understand their fundamentals, one must first comprehend their structure and operation. Typically, these robotic arms consist of joints and links, mimicking the movement of a human arm. The joints might be rotary or linear, allowing the robot to perform a wide variety of tasks, from welding and painting to assembly and packaging. This versatility makes them essential in manufacturing environments where repetitive and precise operations are crucial.

Programming is another critical aspect of industrial robotic arms. They can be programmed using various methods, including teach pendant programming, where operators manually guide the arm through tasks, and sophisticated software that allows for complex automation sequences. Additionally, advancements in artificial intelligence enable these robotic systems to learn and adapt over time, improving their efficiency and reducing downtime. Understanding these fundamentals not only highlights the technology's capabilities but also opens the door to exploring its future applications in manufacturing and beyond.

How to Analyze the Benefits of Robotic Automation in Manufacturing

The integration of robotic automation into manufacturing processes presents numerous benefits that are becoming increasingly quantifiable. According to a report by the International Federation of Robotics (IFR), the global market for industrial robots is projected to reach $70 billion by 2025, driven by advancements in technology and a growing demand for efficiency. Robotic arms can operate continuously, delivering around-the-clock production capabilities that significantly enhance output. In fact, studies indicate that companies adopting robotic systems can achieve productivity increases of up to 30% compared to traditional manufacturing methods.

Moreover, the financial advantages of robotic automation are compelling. A report from McKinsey & Company suggests that automating just 60% of tasks in manufacturing can lead to a net economic benefit of $1.5 trillion by 2030. This can be attributed to reduced labor costs, improved product quality, and minimized waste. The precision of robotic arms not only streamlines processes but also decreases the likelihood of human error, thereby enhancing overall operational efficacy. As businesses navigate the complexities of modern manufacturing, the ability to analyze and leverage these benefits will be crucial for maintaining a competitive edge in an evolving market.

How to Integrate Robotic Arms into Existing Production Lines

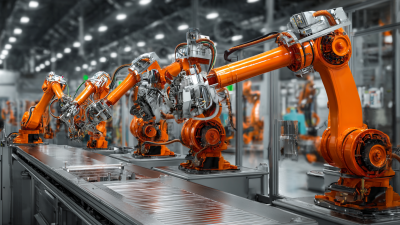

Integrating robotic arms into existing production lines is a strategic move that can enhance efficiency and optimize workflows. The first step in this integration process involves a thorough assessment of the current manufacturing setup. Identifying areas where robotic arms can add value—such as repetitive tasks, precision assembly, or material handling—is crucial. It's important to select robotic arms that align with the specific needs of the production line and assess their compatibility with existing machinery.

Once the appropriate robotic arms have been chosen, the next step is to implement a phased approach to integration. This can involve pilot projects to test the robots in real-world scenarios, allowing for adjustments based on performance data. Training staff to work alongside the robots is equally important, as it fosters a collaborative environment and ensures that human workers understand how to leverage robotic technology effectively. By prioritizing these steps, manufacturers can seamlessly incorporate robotic arms into their operations, leading to increased productivity and reduced operational costs.

How to Overcome Common Challenges in Implementing Robotics

Implementing robotics in manufacturing is a transformative journey, yet it comes with its share of challenges. A report from the International Federation of Robotics (IFR) indicates that around 27% of companies report difficulties in integrating robotic systems with existing workflows. To overcome these hurdles, organizations should prioritize detailed feasibility studies that assess both technical capabilities and workforce training requirements. An investment in training can enhance employee engagement and reduce resistance, as data from McKinsey reveals that companies that adequately prepare their workforce experience 30% higher efficiency in robot deployment.

Another common challenge is the initial cost of automation technology. According to the Boston Consulting Group, the average payback period for industrial robots is about 3 to 5 years, which can deter organizations from moving forward. To mitigate financial constraints, manufacturers are encouraged to explore leasing options for robotic equipment or collaborating with automation partners to share the financial burden. Additionally, implementing a phased approach to robotics—starting with low-risk, high-impact areas—allows for incremental investments and gradual adaptation, fostering a smoother transition toward a fully automated environment.

How to Measure the Impact of Robotics on Manufacturing Efficiency

Measuring the impact of robotics on manufacturing efficiency involves several key metrics that provide insight into productivity and cost-effectiveness. First, cycle time reduction is a primary indicator; as robotic arms automate repetitive tasks, the time taken to complete each cycle decreases significantly. This not only speeds up production but also enables manufacturers to increase their output without compromising quality. Analyzing before-and-after scenarios of cycle times can demonstrate the tangible benefits of integrating robotic technology into the manufacturing process.

Another important metric is the overall equipment effectiveness (OEE), which combines availability, performance, and quality into a single measure. By comparing the OEE before and after implementing industrial robots, manufacturers can evaluate improvements in equipment utilization and identify areas that still require optimization. Additionally, tracking labor costs and turnover rates provides further clarity on the economic impact of robotics. As robotic arms take on more labor-intensive roles, companies can streamline their workforce, reduce labor costs, and minimize the disruptions caused by high turnover. Together, these metrics present a comprehensive picture of how industrial robotic arms enhance manufacturing efficiency and drive innovation in the sector.

Related Posts

-

The Future of Work How Industrial Robots are Transforming Manufacturing Industries

-

Discover the Future of Companionship: How Robot Pets are Changing Lives

-

Transforming Logistics: Cobot Palletizers at the 138th Canton Fair 2025 – Industry Insights and Innovations

-

Exploring the Future of Online Robots in Everyday Life and Digital Interactions

-

Unleashing Digital Transformation: The Ultimate Guide to Robotic Process Automation Software

-

Exploring Robotic Process Automation Tools at the 2025 China 138th Canton Fair Insights and Innovations

Smart Robotics brand movie

Watch video