Exploring the Future of Palletizing Robots at the 138th China Import and Export Fair 2025

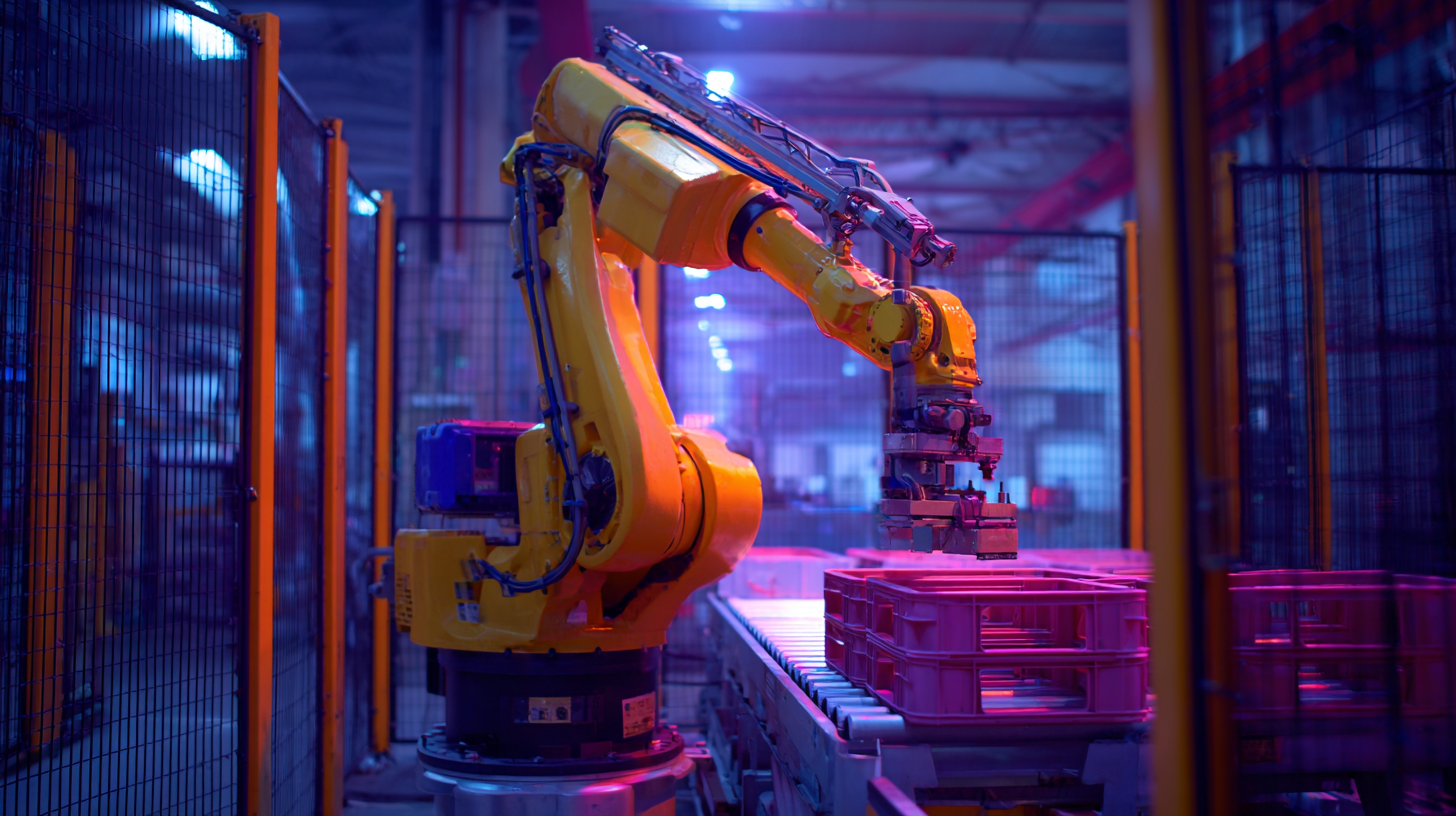

The 138th China Import and Export Fair in 2025 is set to showcase significant advancements in the field of automation, particularly with palletizing robots. As the global market for industrial robots continues to expand—projected to reach $70 billion by 2027, according to a report by MarketsandMarkets—the demand for efficient and reliable palletizing solutions is on the rise. Palletizing robots are increasingly adopted across various industries, driven by the need for enhanced productivity and reduction of labor costs. A comprehensive study by the International Federation of Robotics indicates that palletizing robots alone accounted for 30% of the total robot installations in the manufacturing sector in 2021. As businesses look for innovative ways to streamline operations and improve workflow, the developments presented at the Fair will likely pave the way for the next generation of palletizing robots, underscoring their vital role in shaping the future of supply chain logistics.

Emerging Trends in Palletizing Robotics for 2025

As we approach the 138th China Import and Export Fair in 2025, the spotlight is on the emerging trends in palletizing robotics that promise to reshape the logistics and manufacturing landscapes. With advancements in artificial intelligence and machine learning, palletizing robots are becoming more adept at handling diverse pallet patterns and optimizing space utilization in warehouses. This not only enhances operational efficiency but also significantly reduces the risk of errors associated with manual palletizing.

Tips: To stay ahead in the competitive market, businesses should consider investing in modular and flexible robotic systems that can adapt to changing product lines. Additionally, integrating real-time data analytics can help in monitoring performance and maintenance needs, ensuring that palletizing operations run smoothly.

The trend towards collaborative robots (cobots) is also gaining traction, allowing for safer and more efficient human-robot interactions. These robots can work alongside human workers, taking on repetitive and physically demanding tasks while fostering a more streamlined workflow. Companies should explore solutions that promote seamless integration of cobots into existing operations, enhancing productivity without compromising on safety.

Tips: Regular training sessions for staff on interacting with new robotic systems can maximize the technology's benefits, leading to smoother transitions and greater acceptance among employees. Adopting a proactive approach to robotics not only prepares businesses for the future but also positions them as leaders in innovation within their sectors.

Key Innovations Showcased at the 138th China Import and Export Fair

At the 138th China Import and Export Fair in 2025, the exhibition floor is set to be a showcase of cutting-edge innovations in palletizing robots. Industry reports indicate that the global market for robotic palletizing is expected to reach USD 2.69 billion by 2026, growing at a CAGR of 8.84% from 2021. This growth is driven by the increasing demand for efficient automation solutions, particularly in sectors like manufacturing and logistics. The fair will feature advancements in AI algorithms, vision systems, and IoT connectivity, enabling robots to enhance their operational efficiency and adaptability in diverse working conditions.

Tips: When evaluating palletizing robots for your business, consider the specific needs of your production line. Look for robots that offer flexibility in handling various product sizes and weights. Additionally, ensure that the robotic systems can integrate seamlessly with your existing software and machinery.

During the fair, attendees can expect to see demonstrations of innovative solutions that leverage machine learning for optimized pallet stacking patterns and real-time monitoring systems. Such capabilities not only reduce wastage but also improve safety and throughput in warehouses. With the integration of smart technologies, companies can strive for a more sustainable and productive future in supply chain operations.

Tips: Pay attention to the ease of programming and user interface of the robots you explore at the fair. User-friendly systems can significantly cut down on training time and operational hiccups.

Impact of AI and Automation on Palletizing Solutions

At the 138th China Import and Export Fair in 2025, the focus on palletizing robots promises to reshape the landscape of logistics and warehousing through advanced AI and automation technologies. The integration of artificial intelligence in palletizing solutions is enhancing efficiencies by optimizing the arrangement of goods. These smart robots analyze incoming inventory, adapt to varying load sizes, and recognize the optimal stacking pattern, minimizing error rates and maximizing space utilization.

Moreover, automation in palletizing processes significantly reduces the reliance on manual labor, thus addressing workforce shortages and lowering operational costs. As companies are increasingly investing in automated solutions, the ability of AI to learn and improve over time will allow these systems to become even more proficient. With advancements in machine vision technology, palletizing robots can swiftly adjust to changes in packaging materials and dimensions, ensuring a seamless flow of operations. This evolution in palletizing not only increases productivity but also enhances the overall safety and reliability of logistics operations in an increasingly demanding market.

Challenges and Opportunities in the Palletizing Robot Market

The palletizing robot market is poised for significant growth, driven by the increasing demand for automation in logistics and warehousing. According to a market research report from Custom Market Insights, the global wood pallets market is projected to exceed USD 220 billion, highlighting the expanding applications of palletizing solutions across various sectors. With the rise in e-commerce and the need for efficient supply chain management, businesses are investing heavily in robotic palletizers and de-palletizers. Reports indicate that this segment is witnessing a transformation, with predictions of robust growth from 2025 to 2035 as companies adopt automation to enhance productivity and reduce labor costs.

Moreover, the food robotics market is also set to flourish, with a focus on safety and compliance driving technological advancements. As highlighted in recent analyses, the emphasis on robots that can ensure food safety and adhere to regulatory standards is crucial in bolstering market growth. The PMMI 2024 State of the Industry report further emphasizes that technology investments, particularly in packaging machinery, are essential for maintaining competitive advantage in the rapidly evolving marketplace. Such developments underline the myriad opportunities and challenges within the palletizing robot sector, as businesses navigate the intricacies of automation in their operations.

Future Applications of Palletizing Robots Across Industries

The 138th China Import and Export Fair in 2025 promises to showcase the latest innovations in palletizing robots, with a significant focus on their future applications across various industries. As automation continues to evolve, businesses are keen on leveraging these advanced robotic solutions to enhance efficiency in warehousing, logistics, and manufacturing sectors. Palletizing robots streamline the packing process by accurately stacking products, minimizing human labor, and reducing the risk of injuries, leading to safer and more productive work environments.

In the food and beverage industry, for instance, palletizing robots can drastically improve operational speed and accuracy in packaging. These robots are equipped with intelligent vision systems, allowing them to handle varied product shapes and sizes safely. Innovative software integration enables seamless communication with other automated systems, creating a fully synchronized production line.

Tip: When considering the adoption of palletizing robots, evaluate your current production processes to identify specific bottlenecks. Tailoring robotic solutions to meet unique operational needs could lead to significant efficiency gains. Additionally, ensure that your staff is adequately trained to work alongside these robots, maximizing productivity and minimizing disruptions during the transition phase.

Related Posts

-

Transforming Logistics: Cobot Palletizers at the 138th Canton Fair 2025 – Industry Insights and Innovations

-

How to Harness the Power of AI Robots for Everyday Tasks

-

Exploring Robotic Process Automation Tools at the 2025 China 138th Canton Fair Insights and Innovations

-

Unleashing Digital Transformation: The Ultimate Guide to Robotic Process Automation Software

-

What Are the Advantages of Using Robotic Process Automation Tools

-

Future of Warehouse Robots at China's 138th Canton Fair 2025 Industry Insights and Market Growth Trends

Smart Robotics brand movie

Watch video