How to Enhance Manufacturing Efficiency with Cobot Robots in Your Business

In today's fast-paced manufacturing landscape, the adoption of collaborative robots, or "cobot robots," has emerged as a pivotal strategy for enhancing operational efficiency. According to a report by the International Federation of Robotics, the global market for cobot robots is projected to reach $12 billion by 2025, reflecting a compound annual growth rate of 42%. These statistics highlight a growing recognition among manufacturers of the significant role cobots play in automating mundane tasks, thereby freeing human workers for more complex and value-added responsibilities. By seamlessly working alongside human operators, cobot robots not only boost productivity but also enhance workplace safety and reduce operational costs. As businesses seek to remain competitive and agile, understanding how to effectively integrate cobot robots into their manufacturing processes becomes essential for driving innovation and achieving sustainable growth.

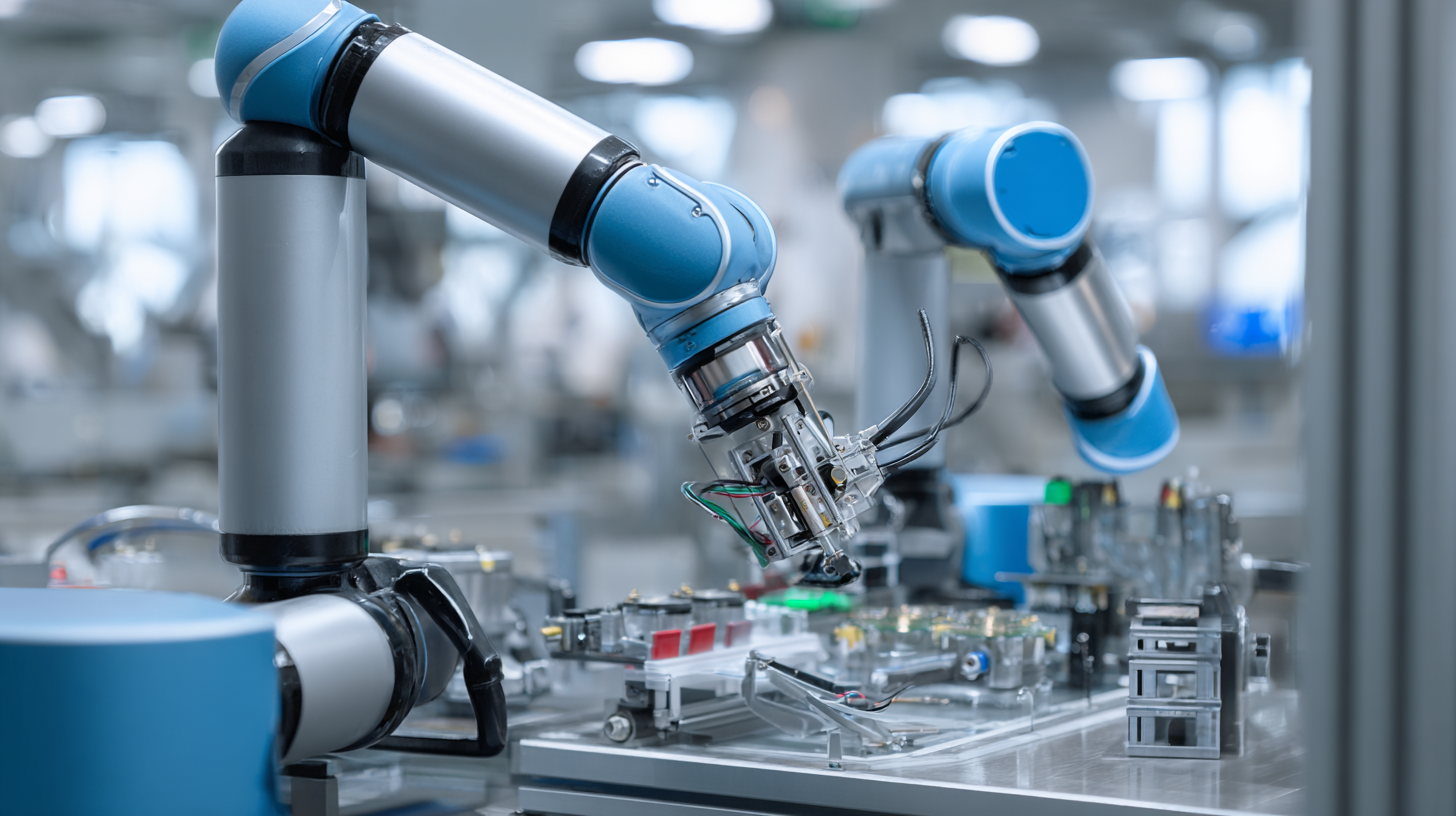

Understanding Cobot Robots: The Future of Collaborative Manufacturing

Cobot robots, or collaborative robots, represent a significant evolution in the landscape of manufacturing. Unlike traditional industrial robots, which are often isolated in gated areas to prevent human interaction, cobots are specifically designed to work alongside humans. This collaboration not only enhances safety but also optimizes workflow efficiency. Manufacturers can leverage these robots to perform repetitive or ergonomically challenging tasks, allowing human workers to focus on more complex, value-added activities that require creative problem-solving and critical thinking.

The future of collaborative manufacturing hinges on the integration of cobot robots into various production processes. Their adaptive programming and user-friendly interfaces enable rapid deployment across numerous applications, from assembly lines to quality control. As the technology continues to advance, cobots are becoming more sophisticated, featuring better sensory feedback and improved machine learning capabilities. This progress empowers businesses to streamline their operations, reduce lead times, and ultimately respond more swiftly to market demands. With the increasing need for agility in manufacturing, adopting cobot robots is not just a trend but a strategic move toward enhanced productivity and competitiveness in the industry.

Identifying Key Areas in Your Production Line for Cobot Integration

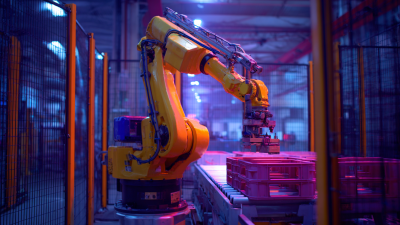

Identifying key areas in your production line for cobot integration is crucial for enhancing manufacturing efficiency. Research indicates that cobots can improve productivity by up to 85% in certain tasks, particularly in repetitive and mundane operations. By strategically analyzing workflows, businesses can pinpoint areas such as assembly stations, welding processes, and material handling where collaborative robots can optimize performance without disrupting existing human roles. For instance, in the welding industry facing a skilled labor shortage, implementing cobot welding cells can greatly alleviate pressure by handling routine welding tasks, thus allowing human workers to focus on more complex jobs.

Identifying key areas in your production line for cobot integration is crucial for enhancing manufacturing efficiency. Research indicates that cobots can improve productivity by up to 85% in certain tasks, particularly in repetitive and mundane operations. By strategically analyzing workflows, businesses can pinpoint areas such as assembly stations, welding processes, and material handling where collaborative robots can optimize performance without disrupting existing human roles. For instance, in the welding industry facing a skilled labor shortage, implementing cobot welding cells can greatly alleviate pressure by handling routine welding tasks, thus allowing human workers to focus on more complex jobs.

Moreover, the integration of cobots into assembly and disassembly lines has shown significant advancements. A literature review suggests that companies that adopt cobots for these purposes experience a reduction in operation time by an average of 30%. Adopting such technology not only streamlines processes but also enhances the adaptability of production environments. With the increasing importance of digitalization and automation, investing in cobots can provide manufacturers with the competitive edge needed to transition from brownfield operations to smart factories, characterized by increased efficiency and higher production flexibility.

Best Practices for Implementing Cobot Robots in Your Operations

Implementing cobot robots in manufacturing operations can significantly enhance efficiency when approached with best practices. First, it’s crucial to assess the specific tasks that can benefit from automation. Identifying repetitive and labor-intensive processes allows businesses to deploy cobots where they can add the most value. Engaging employees in this decision-making process not only ensures that the cobots complement existing workflows, but also fosters a culture of collaboration between human workers and robots.

Training is another vital aspect of successful cobot integration. Workers should receive thorough training on how to operate and collaborate with the robots safely and effectively. This training not only increases workers’ comfort levels with the technology but also enhances operational efficiency, as skilled employees can maximize the potential of cobots. Additionally, continuously monitoring and refining the processes post-implementation helps to identify further improvements and ensures that the cobots adapt to changing manufacturing needs. Emphasizing these best practices will lead businesses to realize the full potential of cobot robots in their operations, driving productivity and efficiency forward.

How to Enhance Manufacturing Efficiency with Cobot Robots in Your Business - Best Practices for Implementing Cobot Robots in Your Operations

| Aspect | Description | Benefits | Key Considerations |

|---|---|---|---|

| Task Automation | Utilizing cobot robots to perform repetitive tasks. | Increased speed and accuracy in production. | Select suitable tasks that require minimal cognitive function. |

| Worker Collaboration | Cobot robots work alongside human operators. | Improved safety and efficiency in the workplace. | Ensure proper training is provided to human workers. |

| Flexibility | Easily reprogrammed for various tasks. | Ability to adapt to changing production needs. | Consider the time and effort required for reprogramming. |

| Cost Efficiency | Reduced labor costs due to automation. | Higher return on investment over time. | Evaluate initial investment versus long-term savings. |

| Scalability | Ability to scale operations easily with additional cobots. | Supports growth without significant increases in costs. | Plan for future expansion and integration. |

Training Your Workforce to Collaborate Effectively with Cobot Robots

Collaborating effectively with cobot robots requires a tailored training approach that empowers workers to maximize their potential alongside these advanced machines. According to a report by the International Federation of Robotics, the market for collaborative robots is projected to grow at a compound annual growth rate (CAGR) of 40% between now and 2026. This rapid expansion underscores the need for workforce training that not only emphasizes technical skills but also integrates soft skills like teamwork and communication. By providing simulations and hands-on experience with cobots, companies can foster an environment where human workers feel confident and capable of interacting with robotic systems.

Moreover, a study published by McKinsey & Company reveals that organizations that invest in training their staff to work with automation saw a productivity boost of up to 30%. Such training programs should tailor their content to address specific roles within the manufacturing process, ensuring that employees understand how to optimize interactions with cobots for improved efficiency. Utilizing augmented reality (AR) and virtual reality (VR) technologies in training can further enhance understanding, bridging the gap between traditional manufacturing practices and the cutting-edge capabilities of cobot collaboration. By prioritizing workforce training in this way, businesses can position themselves to reap the benefits of increased productivity and innovation.

Measuring and Optimizing Efficiency Gains from Cobot Utilization

To measure and optimize efficiency gains from cobot utilization, businesses must first establish clear metrics aligned with their operational goals. Key performance indicators (KPIs) such as cycle time, production volume, and labor costs offer valuable insights into how cobots are impacting overall productivity. By conducting a baseline assessment before introducing cobots, companies can gauge improvements and identify areas requiring further enhancement.

Once the initial data is collected, ongoing analysis becomes vital. Implementing real-time monitoring systems can provide instant feedback on cobot performance and operational efficiency. This allows for timely adjustments in workflows and processes, ensuring that organizations maximize the benefits of their cobot investment. Regularly reviewing and updating these metrics against industry standards can also help in refining strategies and achieving continuous improvement, ultimately leading to a more streamlined manufacturing process.

Related Posts

-

Exploring Robotic Process Automation Tools at the 2025 China 138th Canton Fair Insights and Innovations

-

Transforming Logistics: Cobot Palletizers at the 138th Canton Fair 2025 – Industry Insights and Innovations

-

Exploring the Future of Palletizing Robots at the 138th China Import and Export Fair 2025

-

How to Harness the Power of AI Robots for Everyday Tasks

-

What Are the Advantages of Using Robotic Process Automation Tools

-

Unleashing Digital Transformation: The Ultimate Guide to Robotic Process Automation Software

Smart Robotics brand movie

Watch video