10 Tips for Choosing the Right Industrial Robotic Arm for Your Business

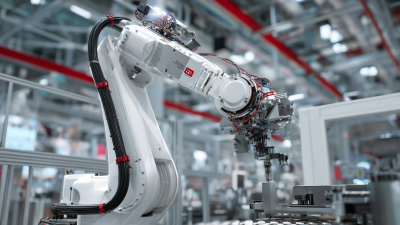

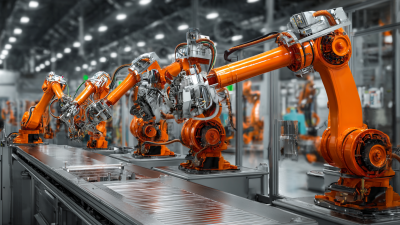

The integration of industrial robotic arms into manufacturing processes has surged dramatically in recent years, with the global market projected to reach $24.8 billion by 2025, according to a report by Markets and Markets. As businesses seek to enhance productivity and efficiency, the need for selecting the right industrial robotic arm becomes paramount. These versatile machines are capable of performing a variety of tasks ranging from assembly and welding to painting and packaging, thus making them indispensable in modern industrial settings.

In navigating the complexities of choosing the appropriate industrial robotic arm, several factors must be considered, including payload capacity, reach, precision, and compatibility with existing systems. A comprehensive understanding of these criteria allows businesses to make informed decisions that align with their operational goals and budget constraints. As industries continue to adopt automation technologies, the ability to effectively select and implement the right robotic solutions will play a critical role in maintaining competitive advantage. With the right insights and strategic planning, companies can leverage industrial robotic arms to not only streamline their processes but also innovate new ways to deliver value in an ever-evolving marketplace.

Understanding Your Business Needs for a Robotic Arm

When considering the adoption of an industrial robotic arm, understanding your business's unique needs is paramount. A study by the International Federation of Robotics highlights that 90% of companies integrating robotic automation report improved productivity and efficiency. Before making a decision, evaluate the specific processes that require automation and the volume of production. For instance, if your operations involve repetitive tasks like welding or assembly, selecting a robotic arm with precision and speed capabilities is essential. Additionally, consider the adaptability of the robotic arm to different product designs, which can significantly affect your operational flexibility.

Furthermore, assessing your current workforce's skill levels can influence your choice. A report from McKinsey states that nearly 60% of jobs in manufacturing could be enhanced through automation. This means that while robotic arms can augment efficiency, it’s equally important to consider how their integration will affect the existing team. Training and upskilling employees will be necessary to harness the full potential of robotic automation. Finally, think about future scalability; choosing a robotic arm that can easily be reconfigured or upgraded will ensure that your investment remains relevant as your business grows.

Evaluating the Types of Industrial Robotic Arms Available

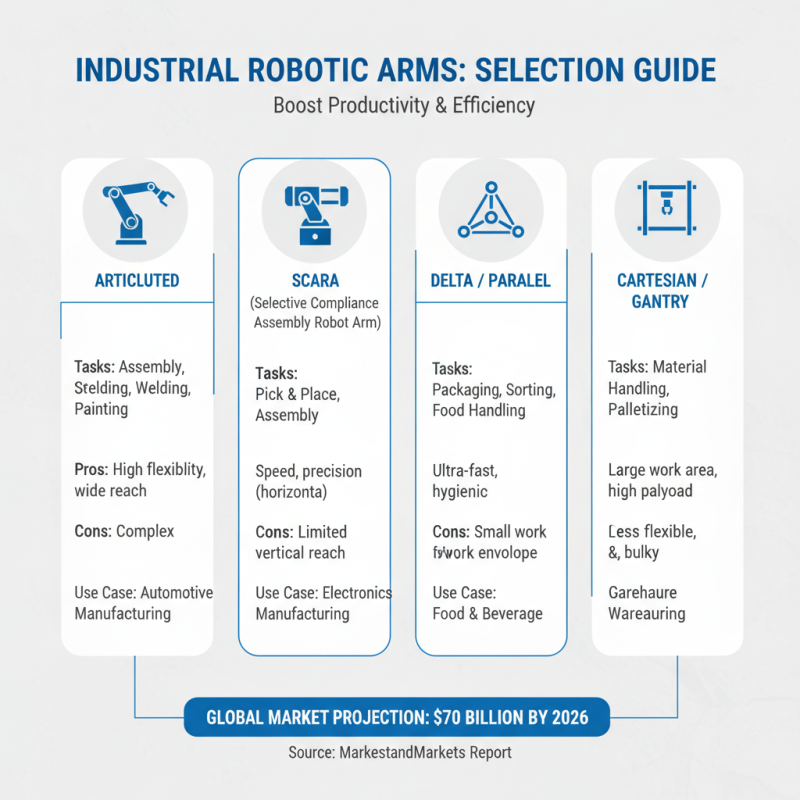

When evaluating the types of industrial robotic arms available, it's essential to consider the specific tasks and applications relevant to your business. According to a recent report by MarketsandMarkets, the industrial robotics market is projected to reach USD 70 billion by 2026, driven by advancements in automation technologies. Different robotic arms serve various functions, ranging from assembly and welding to packaging and material handling. Understanding the nuances between available types can significantly influence productivity and efficiency in manufacturing processes.

Articulated robotic arms, which mimic the movements of a human arm, remain among the most versatile and widely used options in the industry. They typically feature six degrees of freedom, enabling them to handle complex tasks with precision. In contrast, Cartesian robotic arms, characterized by their linear movement along the X, Y, and Z axes, are commonly used for pick-and-place functions due to their simplicity and accuracy. Furthermore, collaborative robotic arms, or cobots, are gaining traction as they are designed to work alongside human operators, enhancing safety and flexibility in shared working environments. Each of these types provides distinct advantages, and the selection process should align with the operational requirements and strategic goals of your business.

Assessing Payload Capacity and Reach Requirements

When choosing the right industrial robotic arm, it's crucial to evaluate both the payload capacity and reach requirements to ensure optimal performance within your specific operational environment. The payload capacity refers to the maximum weight the robotic arm can handle effectively. Understanding your products and materials is essential; for instance, if you're dealing with heavy components, select a robotic arm with a higher payload capacity. This will prevent operational failures and maintain efficiency on the production line.

Additionally, consider the reach of the robotic arm. Assess the workspace layout and the distance the arm needs to cover while performing tasks. The reach is defined by the maximum distance from the base to the end effector, and selecting an arm with insufficient reach can lead to inefficiencies and operational bottlenecks. For optimal functionality, ensure that the selected robotic arm can comfortably navigate around the designated workspace while handling the necessary payloads.

When assessing your specific needs, be mindful of the tasks your robotic arm will perform. It’s essential to match the arm's specifications with the complexity and frequency of your operations. This will help in maximizing productivity while minimizing wear and tear on the robotic system. Taking the time to carefully analyze these key factors will lead to a more informed and effective purchasing decision, ultimately benefiting your business's automation strategy.

Payload Capacity and Reach of Different Industrial Robotic Arms

Considering the Integration with Existing Systems

When selecting an industrial robotic arm, it is crucial to consider how well it will integrate with your existing systems. A seamless integration ensures that the robotic arm can communicate effectively with your machinery, software, and workflows, enhancing overall productivity. Begin by assessing the compatibility of the robotic arm's control systems with your current setup. Look for systems that support standardized communication protocols, which can facilitate smoother interactions between devices.

Another important aspect is the flexibility of the robotic arm to adapt to your manufacturing processes. The ideal robotic arm should not only meet the current requirements but also be scalable for future expansions. Consider how the arm can be programmed to work alongside existing equipment, minimizing disruptions during the initial installation. An investment in user-friendly software tools can ease the integration process, providing operators with the capability to quickly adapt the robotic arm to different tasks as needed. Ultimately, a well-integrated robotic arm can significantly strengthen your operational efficiency and drive innovation within your business.

10 Tips for Choosing the Right Industrial Robotic Arm for Your Business - Considering the Integration with Existing Systems

| Tip Number | Tip Description | Considerations for Integration |

|---|---|---|

| 1 | Assess Your Automation Needs | Ensure compatibility with current production processes. |

| 2 | Evaluate Payload Capacity | Match capacity with the weight of materials handled. |

| 3 | Consider Reach and Range | Ensure reach accommodates all operational areas. |

| 4 | Review End-Effector Options | Check for custom tooling requirements. |

| 5 | Understand Control Systems | Ensure compatibility with existing software. |

| 6 | Examine Safety Features | Evaluate safety measures for collaborative environments. |

| 7 | Analyze Space Requirements | Determine floor space and operational layout. |

| 8 | Consider Maintenance and Support | Check for availability of technical support. |

| 9 | Evaluate Total Cost of Ownership | Analyze all costs including installation and downtime. |

| 10 | Future-Proofing and Scalability | Consider potential for future upgrades and integration. |

Analyzing Cost vs. Long-Term Benefits of Investment

When considering an investment in industrial robotic arms, a complex balance between upfront costs and long-term benefits must be analyzed. The initial capital expenditure for high-quality robotic arms can be substantial, often ranging from $25,000 to over $100,000 depending on the specifications and capabilities. However, according to a recent report by the International Federation of Robotics, the average return on investment (ROI) for businesses adopting robotics can be realized within 1 to 2 years due to increased efficiency and productivity.

A study from Deloitte highlighted that organizations utilizing robotic automation reported up to a 30% increase in overall productivity. Furthermore, robotic arms can significantly reduce labor costs and minimize human errors, leading to substantial savings in quality control and rework expenses. Over a five-year period, companies may experience a cumulative savings of 20-30% of their operational costs, making the long-term financial benefits far outweigh the initial investment. With the industrial landscape increasingly leaning towards automation, these robotic solutions not only provide immediate operational advantages but also strengthen a company’s competitive edge in the market. Investing in industrial robotic arms is a strategic decision that can lead to sustainable growth and profitability in the long run.

Related Posts

-

Why Industrial Robotic Arms Are Revolutionizing Modern Manufacturing Processes

-

10 Essential Tips for Choosing the Right Industrial Robots for Your Business

-

The Future of Work How Industrial Robots are Transforming Manufacturing Industries

-

Top 5 Robotics Companies Driving $110 Billion Global Market Growth in 2023

-

Top 10 Benefits of Using Cobot Palletizers in Modern Warehousing

-

Top 10 Benefits of Robotic Automation for Modern Businesses

Smart Robotics brand movie

Watch video