2026 Top Trends in Cobot Palletizers What to Expect?

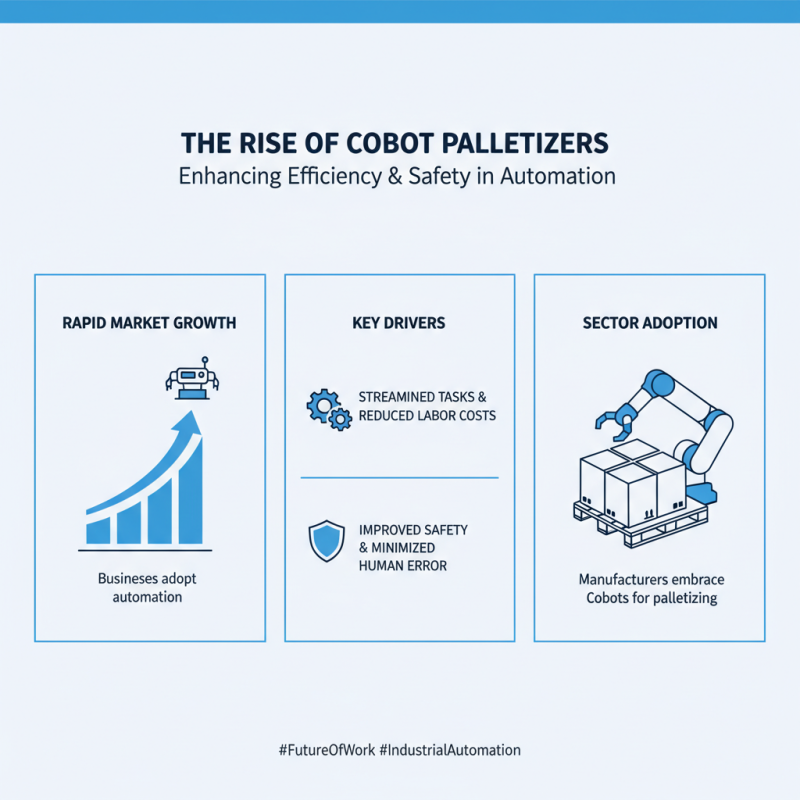

The market for cobot palletizers is evolving rapidly. As we approach 2026, businesses must stay informed about emerging trends. Cobot palletizers are designed to work alongside human operators. This collaboration is driving efficiency in warehouses and production lines.

One significant trend is the integration of advanced AI and machine learning. These technologies enhance the decision-making capabilities of cobot palletizers. They can adapt to various product shapes and sizes. This flexibility is crucial as companies aim to increase productivity while reducing labor costs.

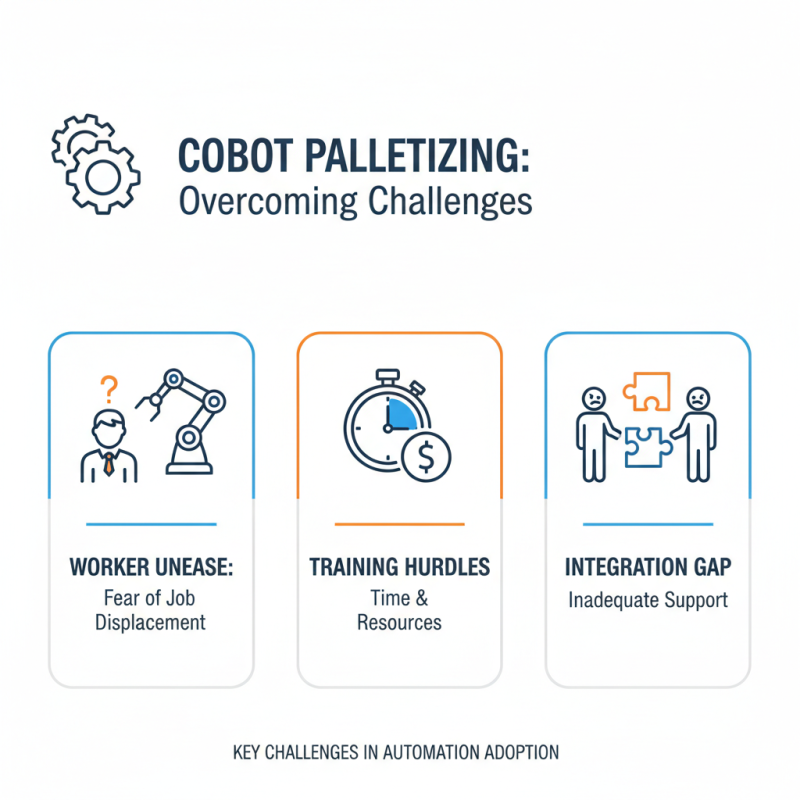

However, some challenges remain. Companies may find it difficult to integrate cobot palletizers into existing systems. Training staff to work with these robots can also pose challenges. As businesses explore these innovations, a cautious approach is necessary. Companies must ensure compatibility with current operations and gain employee buy-in. Understanding potential hurdles can lead to more successful adoption of cobot palletizers.

Emerging Technologies in Cobot Palletizers for 2026

The future of cobot palletizers is bright, with several emerging technologies set to reshape the industry by 2026. A recent report indicates that the global market for collaborative robots, or cobots, is expected to grow to approximately $12 billion by 2026. This growth is fueled by increasing demand for automation in sectors like

logistics and manufacturing.

One key trend is the integration of advanced machine learning algorithms. They enable cobots to learn from their environment and improve efficiency over time. This means that cobots will increasingly adapt their movements based on real-time data. For example, they might optimize their palletizing patterns according to varying product sizes or shapes. However, this adaptability comes with challenges. Companies must carefully train these systems to avoid costly errors.

Additionally, there's a growing interest in modular designs for palletizers. These systems can be easily reconfigured for different tasks. While this flexibility is beneficial, it requires consistent maintenance. A study found that about 30% of companies find it difficult to maintain such systems. Addressing these concerns is essential to fully leverage the capabilities of cobot palletizers.

Key Features to Expect in Next-Gen Cobot Palletizers

The next generation of cobot palletizers is set to redefine automation in various industries. Key features to expect include

enhanced adaptability. These cobots will quickly adjust to handle different product sizes and weights. Such flexibility makes them invaluable for companies facing varying demands.

The ability to switch tasks seamlessly is crucial in dynamic environments.

Another important aspect is improved safety features. New cobot models will focus on collaborative operations. They will use

advanced sensors to detect human presence. This ensures a safe working environment without compromising productivity.

Real-time monitoring will enhance overall efficiency but may introduce complexities in integration. Companies must consider the balance between safety and operational demands.

Additionally, we may see greater connectivity with IoT capabilities. This integration will allow

real-time data analysis and predictive maintenance. However, this raises concerns about data management.

The potential for cybersecurity threats is ever-present. Businesses will need to invest in secure systems and training to mitigate risks.

Though exciting, these advancements come with their own set of challenges.

Impact of AI and Machine Learning on Cobot Performance

The integration of AI and machine learning into cobot palletizers is transforming the industry. In 2026, we expect these technologies to enhance cobot performance significantly. According to recent industry reports, AI-driven cobot systems can improve operational efficiency by up to 25%. This advancement hinges on better data collection and analysis, allowing cobots to adapt to various tasks in real time.

One area to watch is how machine learning algorithms can optimize palletizing patterns. These algorithms analyze historical data to determine the most efficient stacking configurations. However, the implementation of these advanced systems does not come without challenges. Some cobots may struggle to handle complex product shapes, leading to potential downtime. Reports indicate that 15% of companies have faced such issues, demonstrating the need for continued development.

Moreover, the reliance on AI raises questions about workforce dynamics. Employees may need new skills to work alongside these advanced systems effectively. Organizations must invest in training programs to bridge this gap. The risks of undertraining could lead to inefficiencies and safety concerns on the factory floor. This highlights a critical balance between automation and human oversight. As AI technology matures, the future of cobot palletizers looks promising, but it requires thoughtful implementation.

2026 Top Trends in Cobot Palletizers What to Expect? - Impact of AI and Machine Learning on Cobot Performance

| Trend | Description | Impact of AI/ML | Expected Adoption Rate (%) |

|---|---|---|---|

| Increased Flexibility | Cobots will adapt to various package sizes and shapes quickly. | AI allows for real-time adjustments based on detected items. | 75% |

| Enhanced Safety Features | Improved sensing technologies reduce workplace accidents. | ML algorithms enhance risk assessment and avoidance. | 80% |

| Data-Driven Optimization | Use of data analytics to improve operational efficiency. | AI processes vast amounts of data for actionable insights. | 70% |

| Seamless Integration | Cobots will integrate with existing systems and software more easily. | AI enables better communication between devices and platforms. | 85% |

| Cost Reduction | Decreasing costs of cobots will expand their market reach. | AI lowers operational costs by enhancing productivity. | 90% |

Market Trends Driving the Adoption of Cobot Palletizers

The market for collaborative robot (cobot) palletizers is growing rapidly. Businesses are seeking ways to enhance efficiency. This shift is driven by the need for automation in various sectors. Manufacturers are now adopting cobots more than ever. These technologies can streamline palletizing tasks, reducing labor costs. They also improve workplace safety by minimizing human error.

Increased demand for flexible automation solutions plays a key role here. Companies want systems that can adapt to different products. Cobots offer that versatility, working alongside human operators. However, the integration process can be challenging. Many firms underestimate the time it takes to train staff. There can be resistance to change within the workforce, too.

With more industries embracing cobots, competition is rising. Cost savings can be significant, particularly for small to medium enterprises. They need efficient systems that won't break the bank. Yet, some businesses may face hurdles in scaling up operations. Proper planning and implementation are essential. Organizations should reflect on their readiness to adopt such technology.

Challenges and Solutions in Implementing Cobot Systems

The implementation of collaborative robot (cobot) systems in palletizing processes is not without its challenges. Workers often feel uneasy about integrating robots into their workflow. There can be a fear of job displacement. Training employees to work alongside cobots requires time and resources. Many companies struggle to provide adequate training, leading to frustration.

Technical difficulties often arise during implementation. Cobots must be properly programmed for specific tasks. Miscommunication between hardware and software can result in errors. It’s important to develop a robust system that addresses this. Regular updates and maintenance are essential as well. However, many organizations overlook this aspect, which affects efficiency.

Integrating cobots calls for a cultural shift in workplaces. Teams need to embrace automation while valuing human input. Resistance from staff can hinder productivity. There needs to be open communication, fostering a collaborative environment where concerns can be addressed. Continuous evaluation of the system’s performance is crucial to identify areas needing improvement. The combination of human oversight and cobot efficiency can lead to better results in palletizing operations.

Related Posts

-

Transforming Logistics: Cobot Palletizers at the 138th Canton Fair 2025 – Industry Insights and Innovations

-

Exploring the Future of Online Robots in Everyday Life and Digital Interactions

-

Why Robotics Engineering is the Future of Innovation and Technology

-

10 Proven Benefits of Robotic Process Automation Software for Boosting Business Efficiency

-

Top 10 Warehouse Automation Robots Transforming Supply Chain Efficiency

-

Revolutionizing Efficiency: The Future of Packaging Robots in Smart Warehousing

Smart Robotics brand movie

Watch video